Disclaimer: Don't build a death star. This content was generated through GenAI services on

Waldo. We do not claim to own any of the content shared here, everything has been referenced or has original sources.

Overview

^ top ^

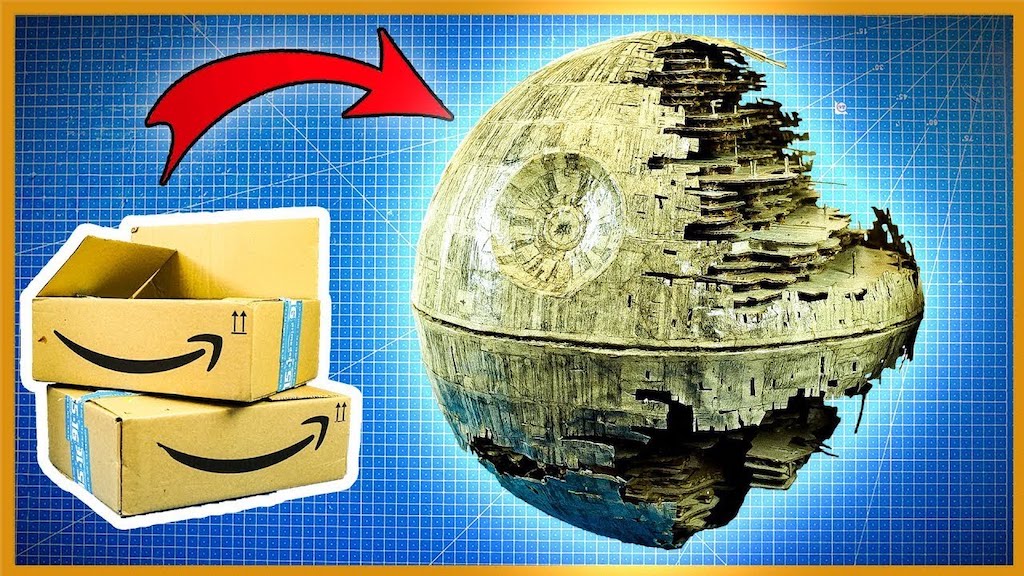

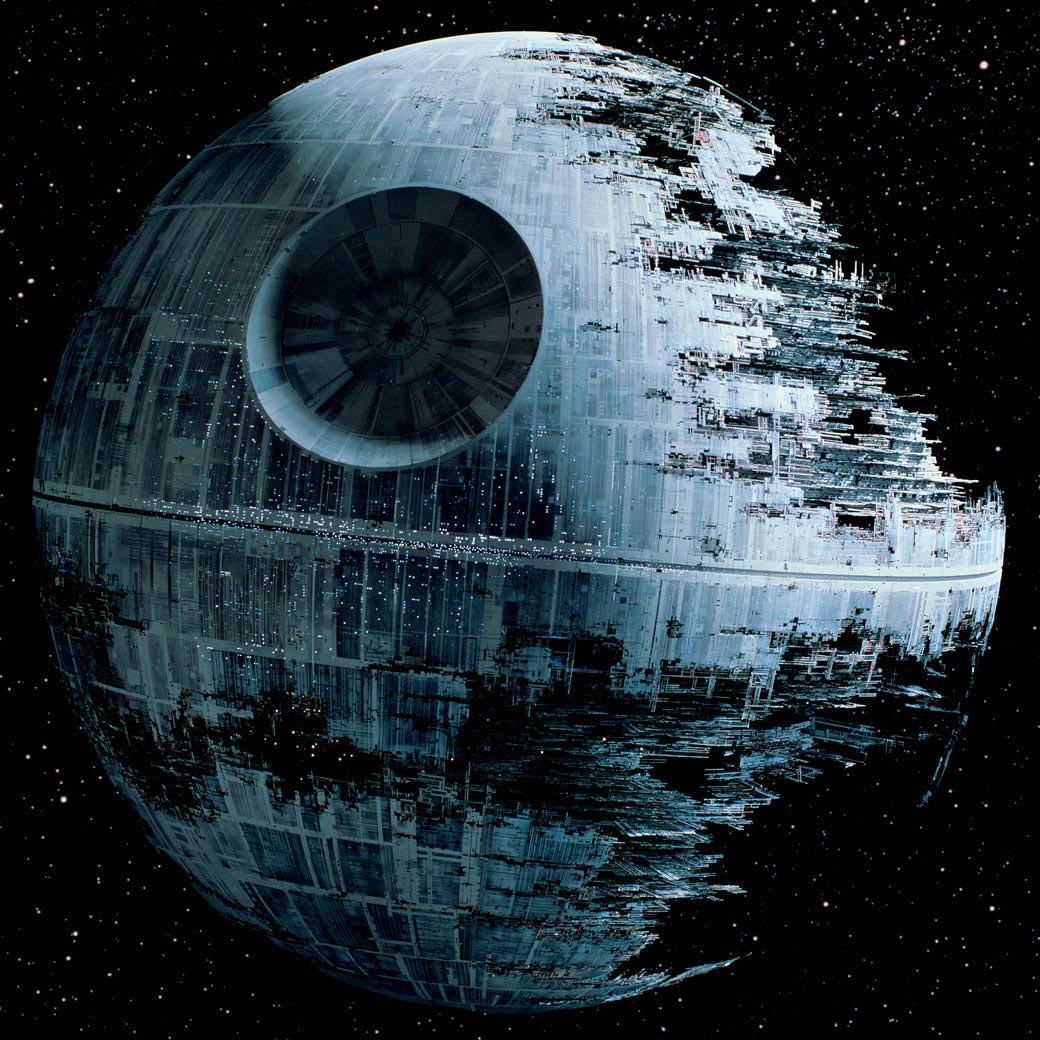

Building a new Death Star, a moon-sized, deep-space mobile battle station, would be a monumental

task requiring extensive planning, resources, and time

[1]

[2].

The original Death Star, designed to execute the Tarkin Doctrine, was approximately 120 kilometers in diameter and

was intended to instill fear and control over the Galactic Empire

[3]

[4].

The concept and design of the Death Star were inspired by the works of artist John Berkey and developed by the

likes of Grand Moff Wilhuff Tarkin and Sienar

[5]

[6].

The construction of such a massive structure would require a vast amount of materials, including

structural, thermal control, shielding, optics, solar arrays, lubricants, seals, and adhesives

[7]

[8].

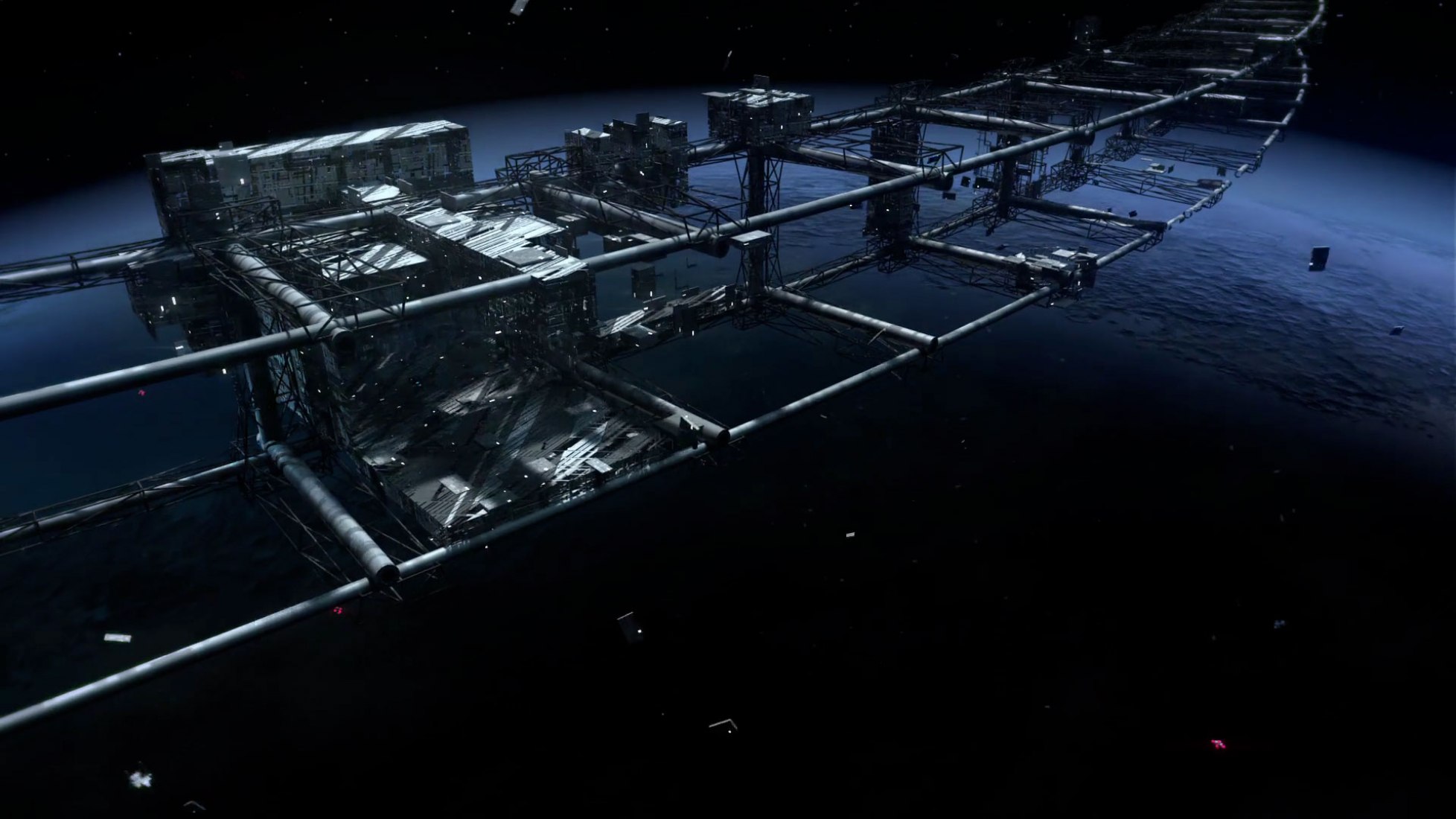

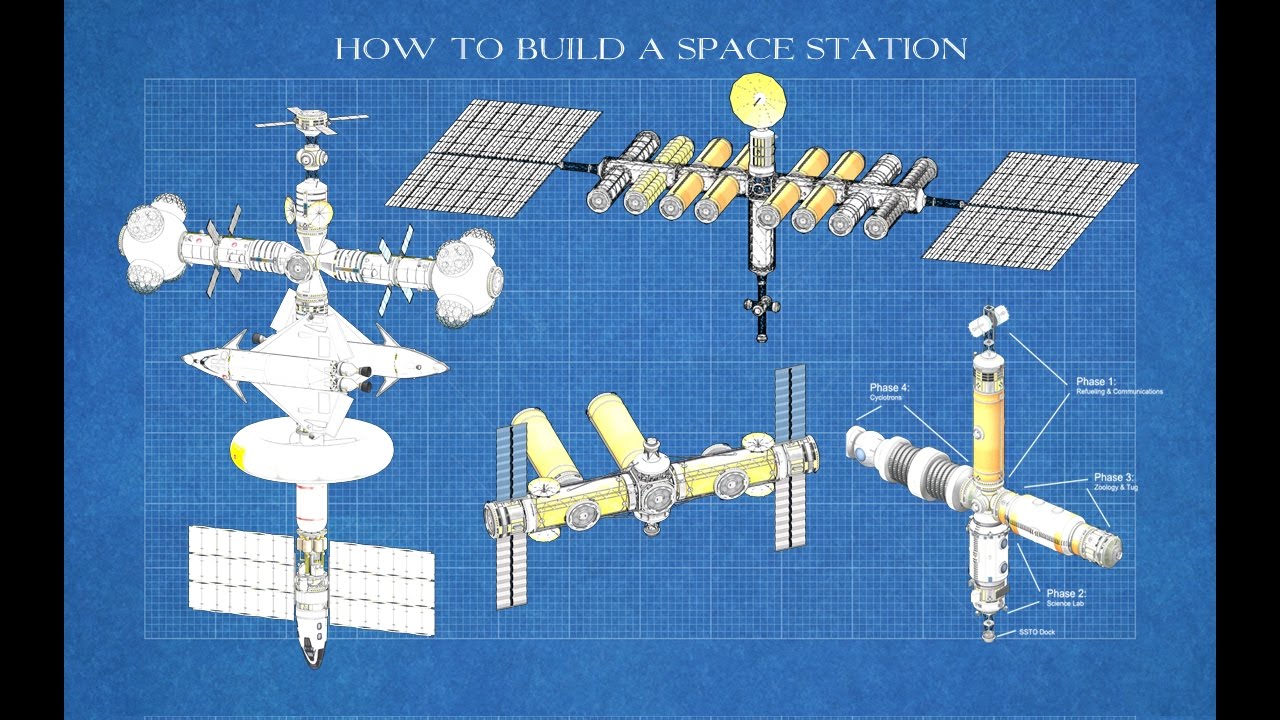

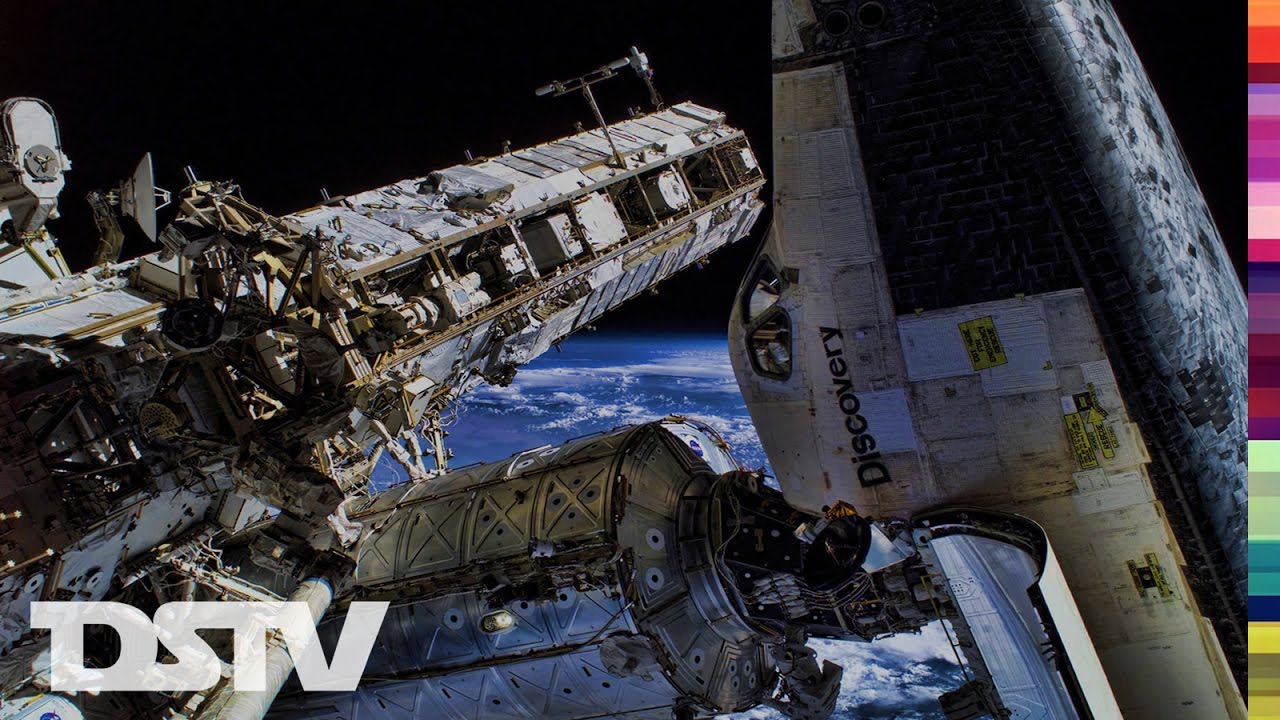

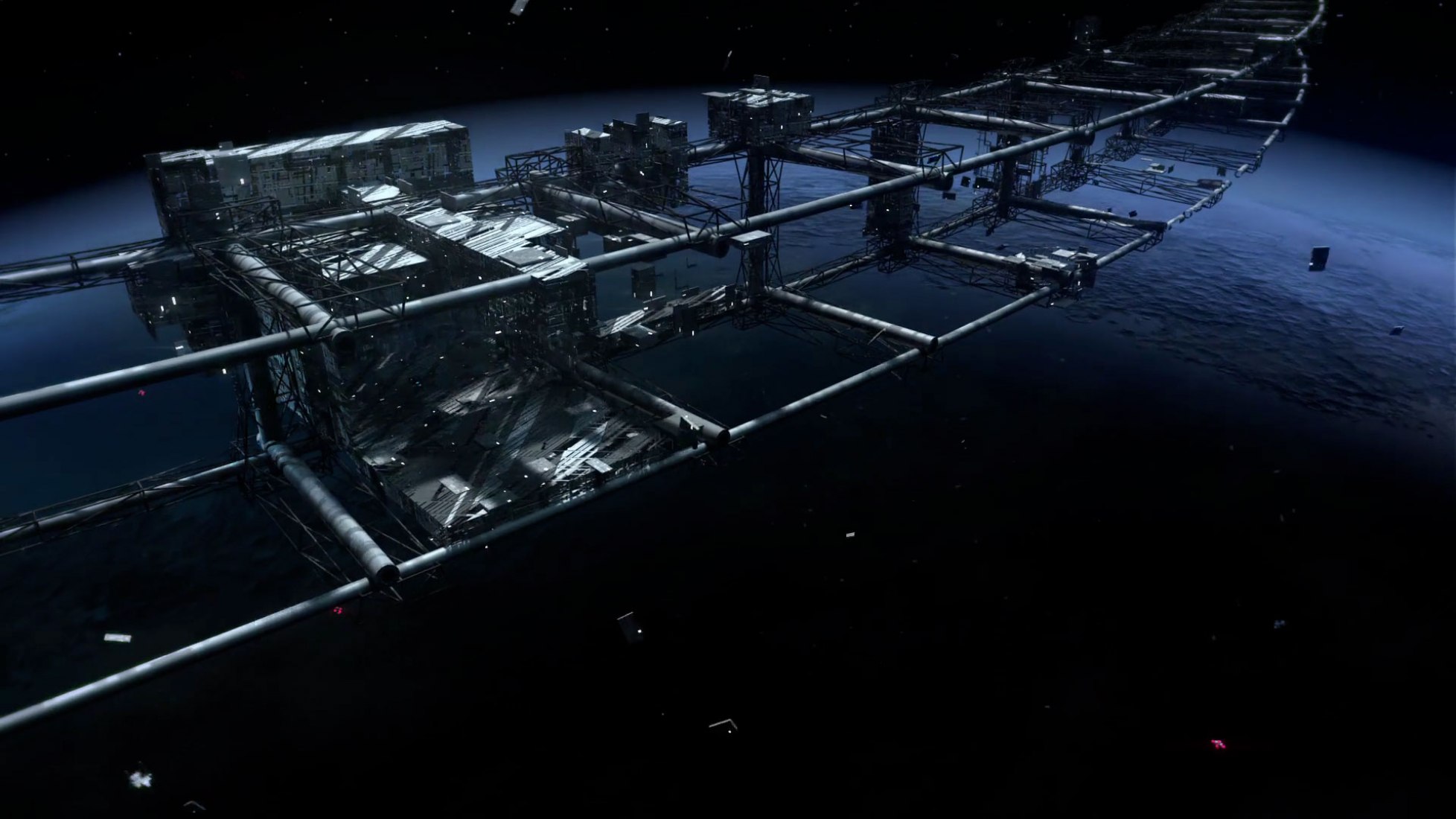

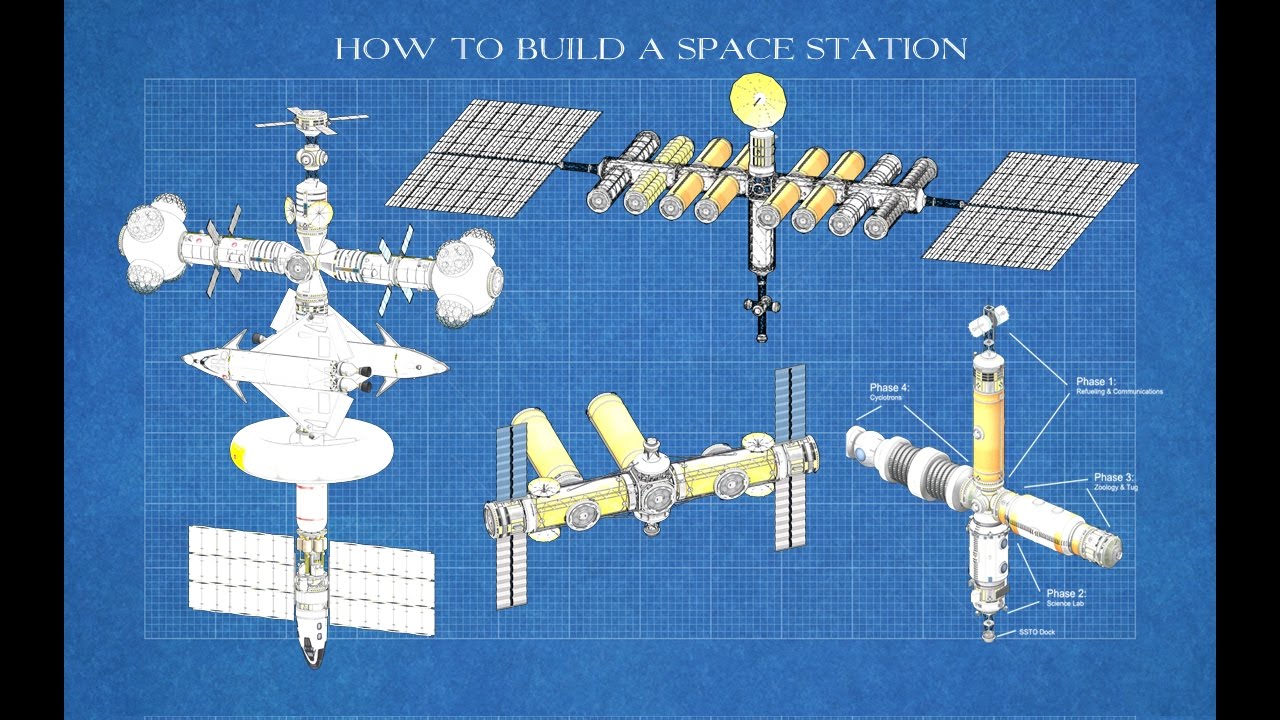

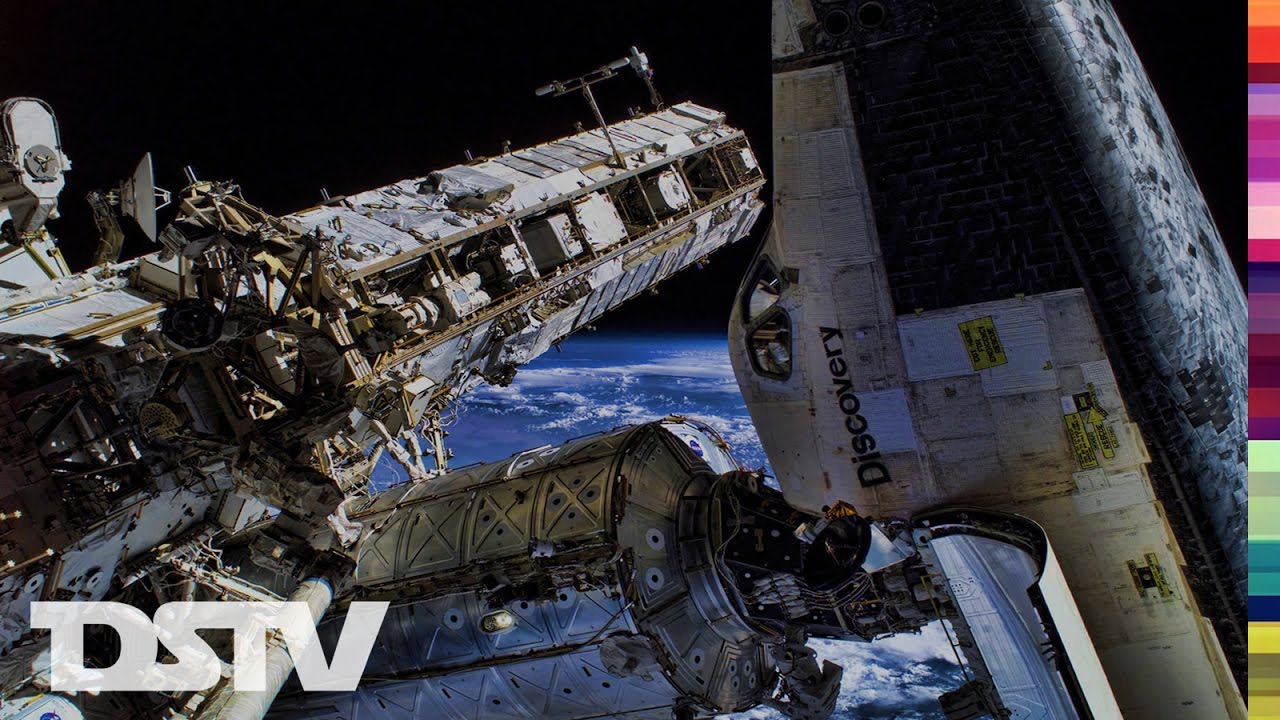

These materials would likely need to be transported to space in stages, similar to the construction of the

International Space Station

[9]

[10].

Technological innovations would be crucial in the construction process. Cutting-edge experiments

and technologies, such as 3D printing construction systems and advanced battery storage, are being developed and

could potentially be utilized

[11]

[12]

[13].

The construction would also require a large workforce, with the original Death Star crewed by 2 million Imperial

personnel

[14].

The project timeline would likely span decades, with the original Death Star taking approximately

20 years to build

[15]

[16].

Risk assessment and mitigation strategies would be essential to manage potential cost overruns, delays, and other

adverse events

[17]

[18]

[19].

Finally, environmental and ethical considerations would need to be addressed. The construction and

operation of a Death Star could have significant environmental impacts, potentially contributing to carbon

emissions and other forms of pollution

[20]

[21].

Ethical considerations would also arise, particularly given the Death Star's intended use as a weapon of mass

destruction

[22]

[23].

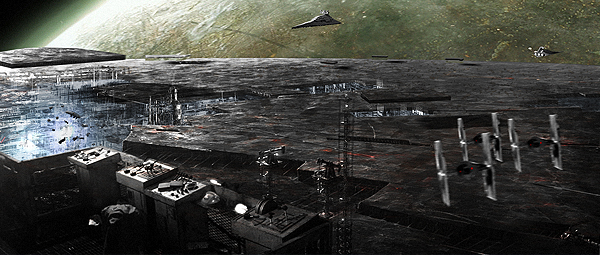

Death Star: Concept and Design

^ top ^

The concept of the Death Star was explored even before the Clone Wars, as part of the Tarkin

Doctrine, which aimed to control the Galactic Empire through fear

[3].

The design of the Death Star was inspired by the artwork of John Burkey, and the models were created by designer

Colin Cantwell

[5]

[24].

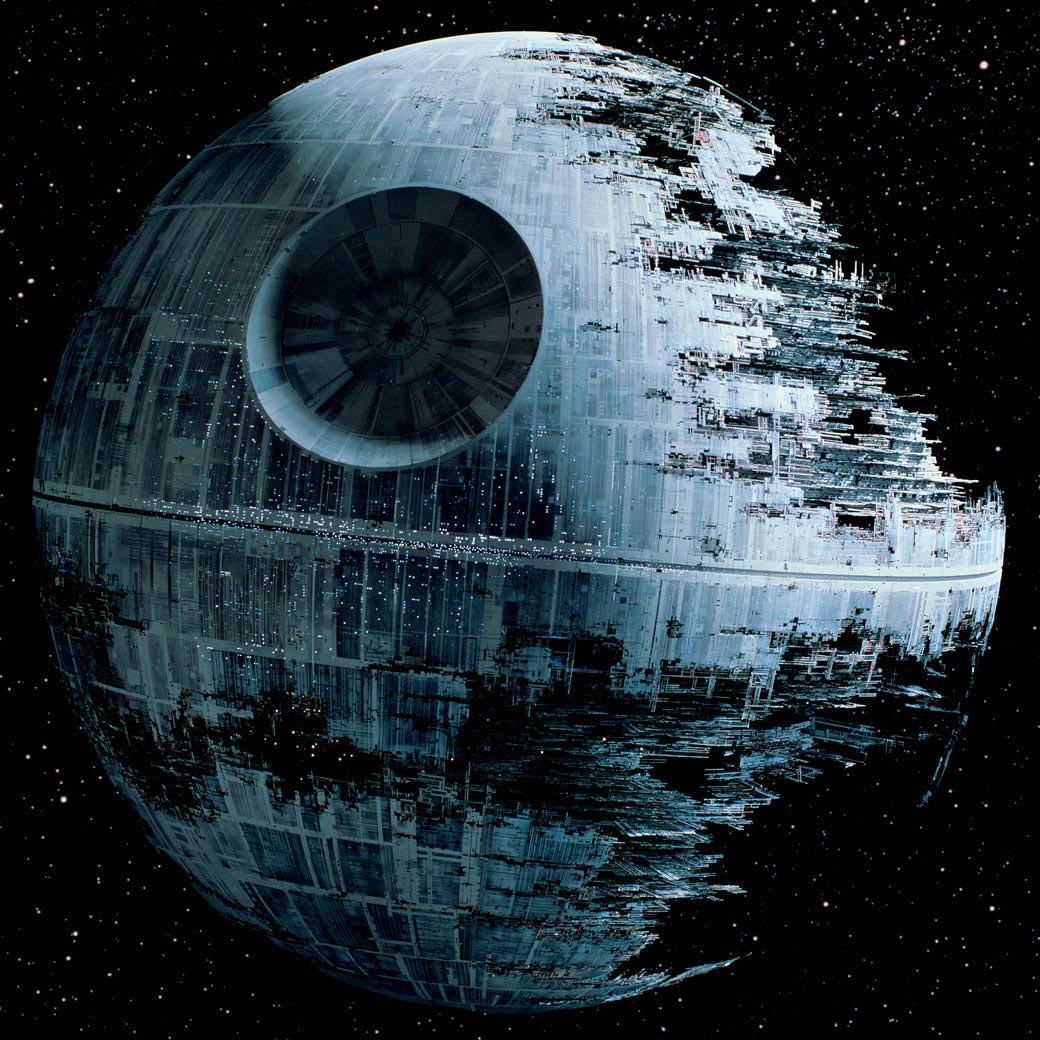

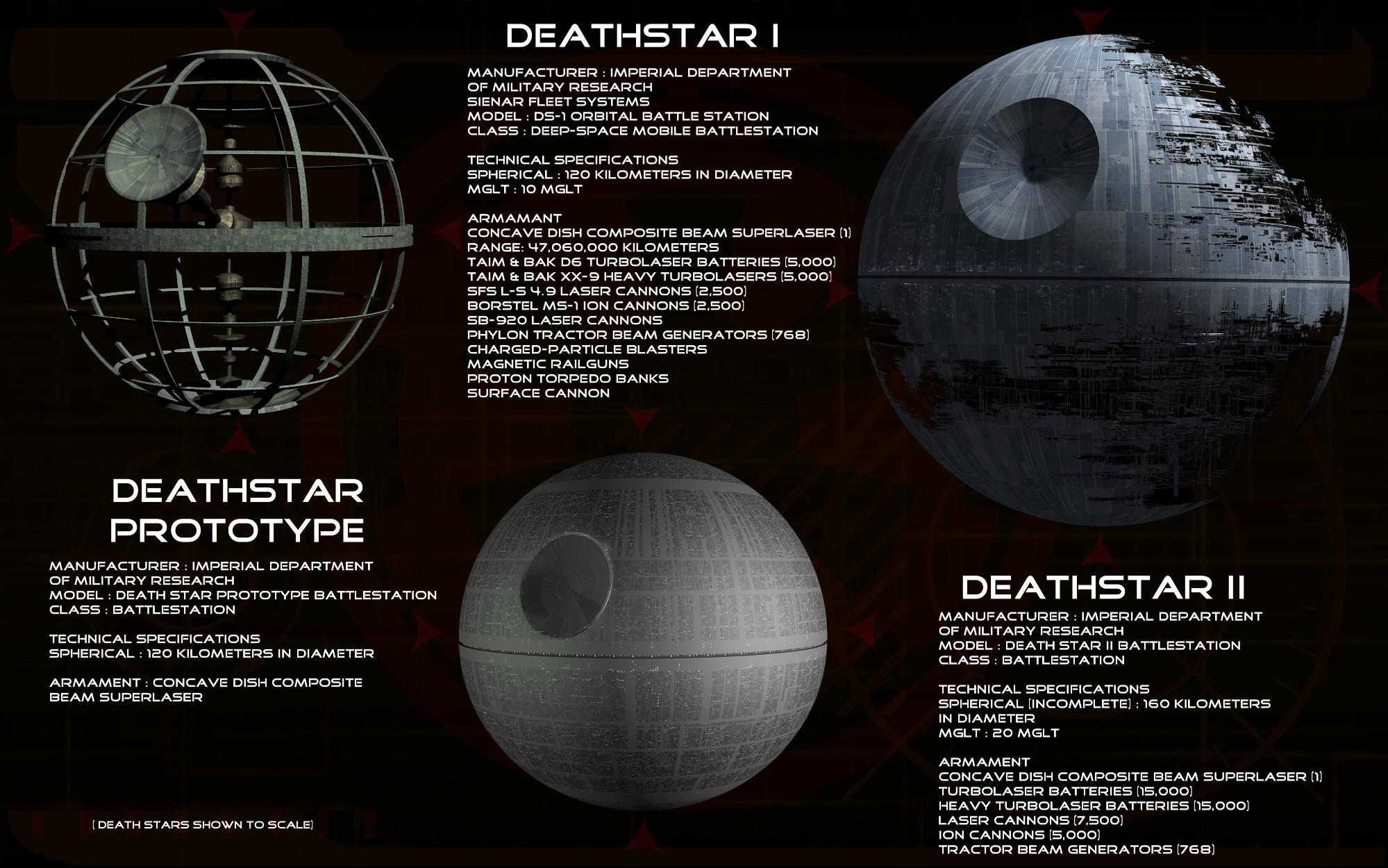

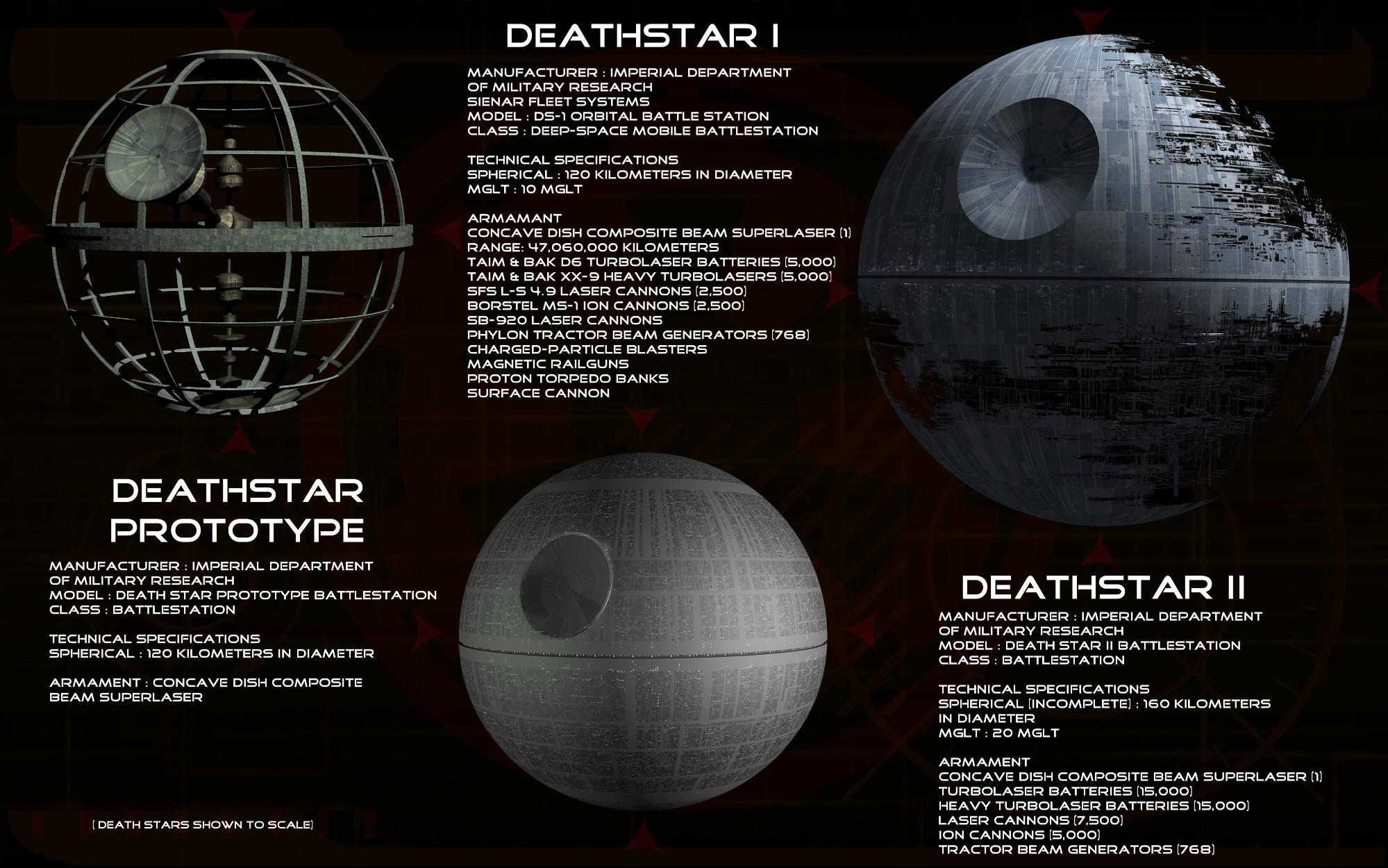

The original design of the Death Star was a sphere the size of a Class-IV moon, measuring 120 kilometers in

diameter

[4]

[2].

The idea for the Death Star began with the Confederacy of Independent Systems designing the Ultimate Weapon, using

plans and concepts provided by Grand Moff Wilhuff Tarkin

[25].

Despite the efforts of the Empire to keep the plans secret, Rebel Alliance spies managed to steal the schematics

[23].

The Death Star is a fictional space station and superweapon featured in the Star Wars franchise,

capable of annihilating entire planets

[1].

The original Death Star, appearing in the 1977 film Star Wars, was destroyed by the Rebel

Alliance. A larger, more advanced second Death Star was constructed and featured in the film Return of the Jedi,

but was also destroyed by the Rebel Alliance

[1].

The concept of the Death Star was not initially included in George Lucas's outline for the

Star Wars saga. The idea was borrowed from the third act when creating the first film

[1].

The Death Star was designed by concept artist and spaceship modeler Colin Cantwell, who had

previously worked with Stanley Kubrick on the 1968 film 2001: A Space Odyssey

[1].

The Death Star's superlaser, capable of destroying entire planets, was powered by a

hypermatter reactor. The station also had a complex network of ion engines and hyperdrive field generators for

mobility

[4].

The first Death Star was 120 kilometers in diameter, while the second Death Star was 160

kilometers in diameter

[4].

However, some sources state smaller figures, with some inconsistencies among various writers for the Star Wars

franchise

[1].

The Death Star was defended by thousands of turbolasers, ion cannons, and laser cannons, and

housed a large number of military personnel, maintenance droids, and civilians

[1].

The Death Star's design had several flaws, including the power systems and the thermal

exhaust port, which was exploited by the Rebel Alliance to destroy the first Death Star

[4].

The second Death Star corrected several design flaws of the original, including the thermal

exhaust port and the surface defenses

[4].

The Death Star has become a cultural icon and a widely recognized element of the Star Wars

franchise, inspiring numerous similar superweapons in fiction as well as in other Star Wars works

[1].

The Death Star is a fictional space station and superweapon featured in the Star Wars franchise,

capable of annihilating entire planets

[1].

The original Death Star, appearing in the 1977 film Star Wars, was destroyed by the Rebel

Alliance. A larger, more advanced second Death Star was constructed and featured in the film Return of the Jedi,

but was also destroyed by the Rebel Alliance

[1].

The concept of the Death Star was not initially included in George Lucas's outline for the

Star Wars saga. The idea was borrowed from the third act when creating the first film

[1].

The Death Star was designed by concept artist and spaceship modeler Colin Cantwell, who had

previously worked with Stanley Kubrick on the 1968 film 2001: A Space Odyssey

[1].

The Death Star's superlaser, capable of destroying entire planets, was powered by a

hypermatter reactor. The station also had a complex network of ion engines and hyperdrive field generators for

mobility

[4].

The first Death Star was 120 kilometers in diameter, while the second Death Star was 160

kilometers in diameter

[4].

However, some sources state smaller figures, with some inconsistencies among various writers for the Star Wars

franchise

[1].

The Death Star was defended by thousands of turbolasers, ion cannons, and laser cannons, and

housed a large number of military personnel, maintenance droids, and civilians

[1].

The Death Star's design had several flaws, including the power systems and the thermal

exhaust port, which was exploited by the Rebel Alliance to destroy the first Death Star

[4].

The second Death Star corrected several design flaws of the original, including the thermal

exhaust port and the surface defenses

[4].

The Death Star has become a cultural icon and a widely recognized element of the Star Wars

franchise, inspiring numerous similar superweapons in fiction as well as in other Star Wars works

[1].

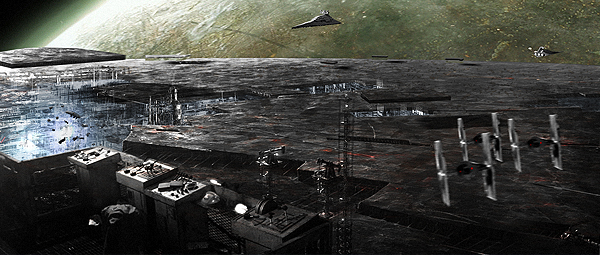

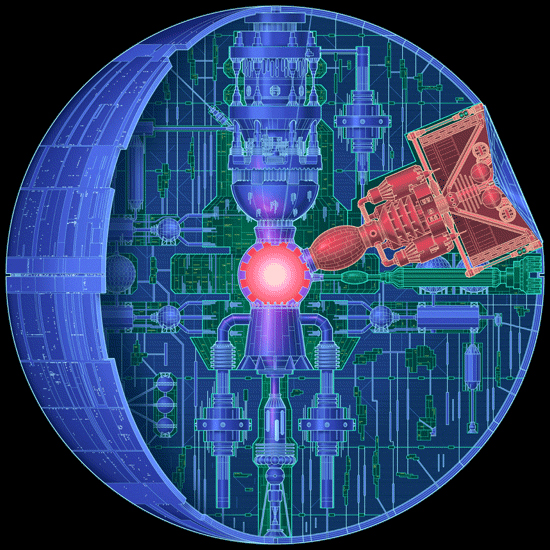

The Death Star, a superweapon of the Galactic Empire, was capable of annihilating entire planets

[1].

It was designed based on Geonosian designs and the plans were codenamed "Stardust"

[26].

The Death Star's architecture included a core and heavily cross-linked segments to aid its structural

integrity

[27].

It was composed of four major components: the battle station, the Superlaser, the propulsion system, and the

hypermatter reactor that powers it

[4].

The Death Star also featured a complex network of real-space ion engines and hyperdrive field generators that

allowed it to travel like any other interstellar space craft

[4].

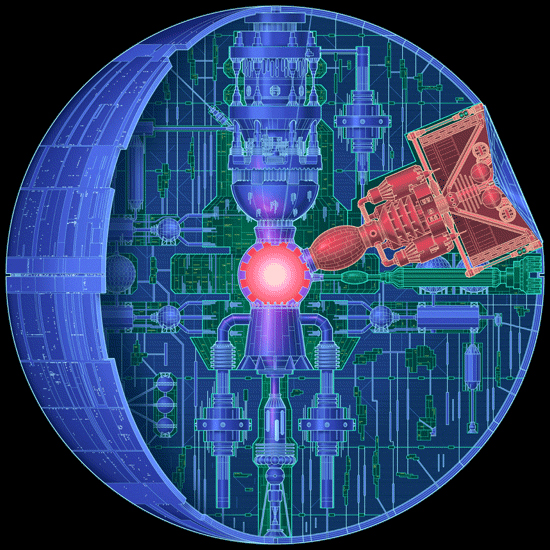

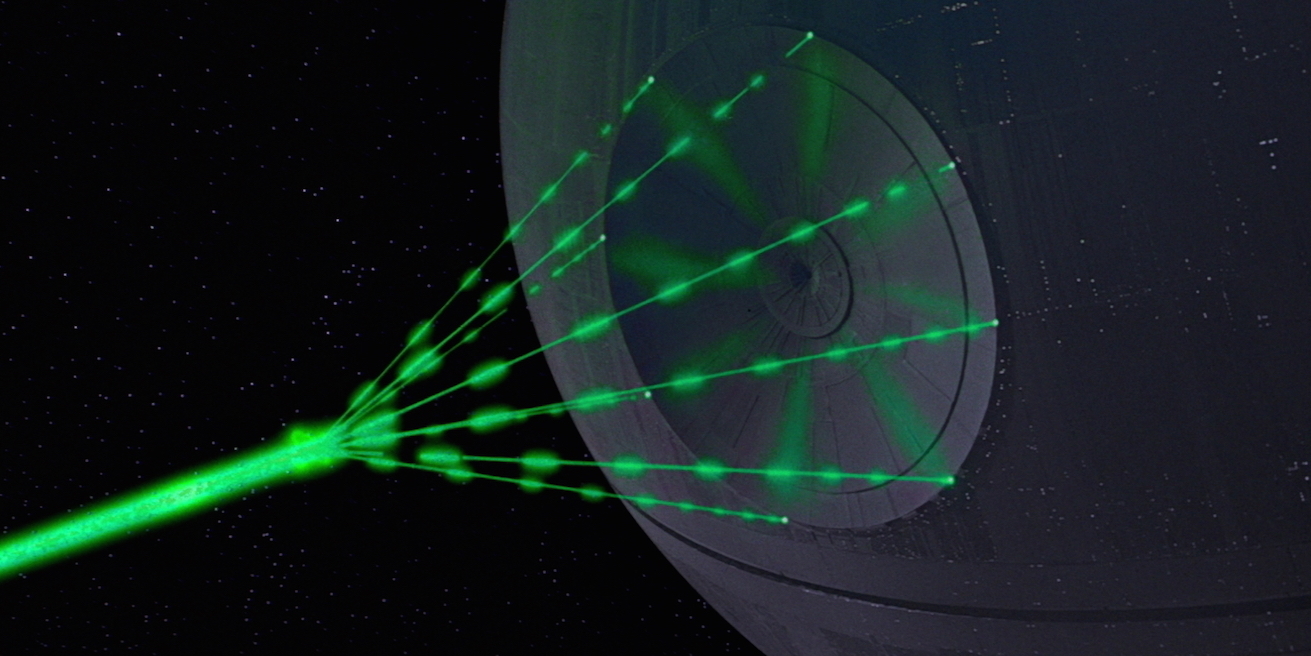

The Death Star's superlaser, a terrifying weapon capable of destroying a planet, was built

around a superlaser array. This design was revived from the ancient Sith who used massive kyber crystals to create

superweapons

[28].

The superlaser worked through the use of special crystals and focusing lenses

[29].

The first Death Star's superlaser was estimated to have a power of more than 2.4×10^32 watts, with an

optimum range of 2,000,000 kilometers and a working range of 420,000,000 kilometers

[30].

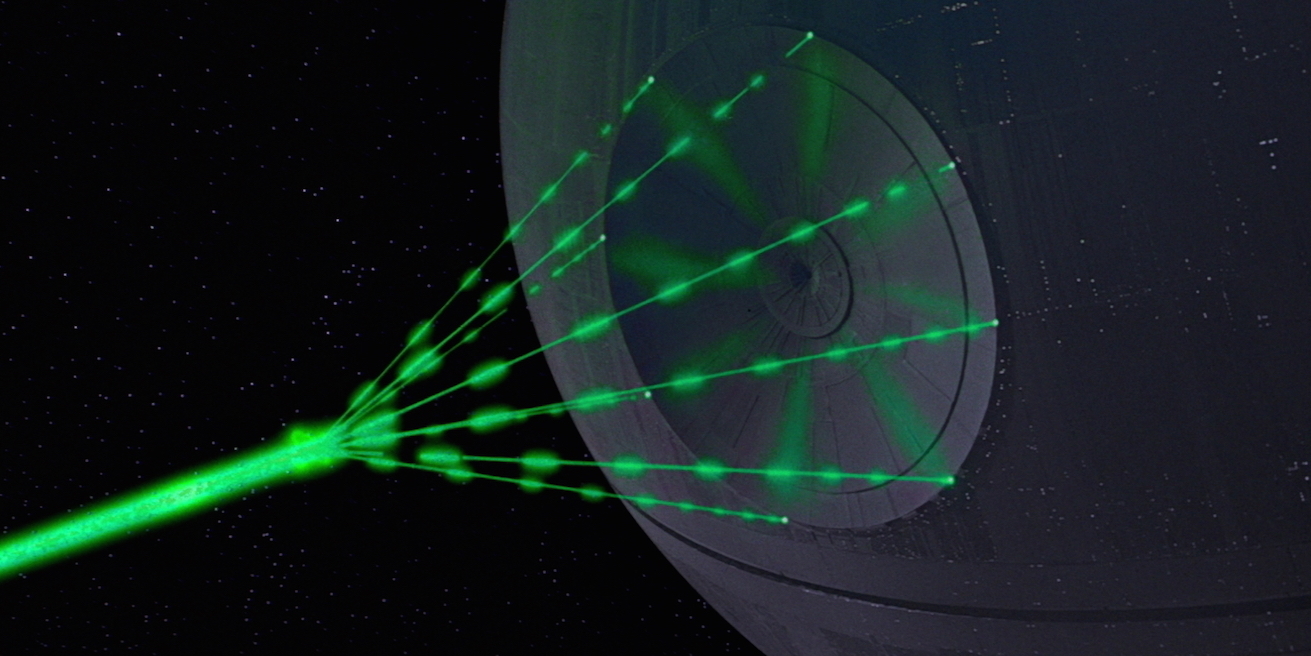

The superlaser used on the Death Stars was a Concave Dish Composite Beam Superlaser, with the first Death

Star's superlaser having eight tributary beams arranged in a circle around the concave dish

[31].

The Death Star's superlaser was a powerful weapon designed to destroy planets. The design

was based on ancient Sith superweapons that used massive kyber crystals

[28].

The superlaser worked through the use of these special kyber crystals and focusing lenses

[29].

The first Death Star's superlaser was powered by eight kyber crystals. Laser beams generated

from these crystals were focused and combined into a single blast

[32].

The superlaser could be fired at lower power to devastate an area encompassing roughly 1/8th of

a planet's surface. The recharge time on the reactors was nearly an entire day

[32].

The second Death Star featured a more powerful superlaser with improved targeting sensors and

power regulators. It could fire with enough force to destroy any capital ship in a single hit, while recharging

for another similar-strength shot in only 3 minutes

[28]

[32].

The First Order's Starkiller Base harbored a superweapon built into the planet's crust

that was capable of destroying entire star systems. This weapon was powered by drawing on the energy of a star

[32].

The First Order also used a miniaturized version of the superlaser to crack open a Resistance

hideout on the planet Crait

[32].

The fallen Emperor returned with hundreds of Xyston-class Star Destroyers, all of which were

armed with powerful axial superlasers that could destroy a planet with a single sustained burst

[32].

The Death Star's superlaser was a powerful weapon designed to destroy planets. The design

was based on ancient Sith superweapons that used massive kyber crystals

[28].

The superlaser worked through the use of these special kyber crystals and focusing lenses

[29].

The first Death Star's superlaser was powered by eight kyber crystals. Laser beams generated

from these crystals were focused and combined into a single blast

[32].

The superlaser could be fired at lower power to devastate an area encompassing roughly 1/8th of

a planet's surface. The recharge time on the reactors was nearly an entire day

[32].

The second Death Star featured a more powerful superlaser with improved targeting sensors and

power regulators. It could fire with enough force to destroy any capital ship in a single hit, while recharging

for another similar-strength shot in only 3 minutes

[28]

[32].

The First Order's Starkiller Base harbored a superweapon built into the planet's crust

that was capable of destroying entire star systems. This weapon was powered by drawing on the energy of a star

[32].

The First Order also used a miniaturized version of the superlaser to crack open a Resistance

hideout on the planet Crait

[32].

The fallen Emperor returned with hundreds of Xyston-class Star Destroyers, all of which were

armed with powerful axial superlasers that could destroy a planet with a single sustained burst

[32].

The design of the Death Star, a fictional space station from the Star Wars franchise, was

influenced by a variety of real-world elements. The devastating power of nuclear and hydrogen bombs served as a

significant inspiration for the battle station's destructive capabilities

[33].

Additionally, the climactic battle sequences, particularly the Rebels' first run on the Death Star, drew

inspiration from war movies such as the 1955 film "The Dam Busters"

[34]

[35].

This film, which depicts an Allied squadron's mission to destroy heavily defended German dams, parallels the

Death Star Trench Run in Star Wars

[35].

Despite the fantastical setting of the Star Wars universe, these influences highlight the franchise's

grounding in real-world history and technology

[33]

[35].

Material and Resource Requirements

^ top ^

The construction of a space station requires a variety of materials, including structural

materials, thermal control materials for on-orbit and re-entry, shielding against radiation and meteoroid/space

debris impact, optics, solar arrays, lubricants, seals, and adhesives

[7]

[8].

The International Space Station (ISS), for example, required shipments of steel, aluminium alloys, and other

materials

[36].

The construction process involves taking the space station into space piece-by-piece and gradually building it in

orbit

[9]

[10].

Additionally, resources from asteroids and other planetary bodies like the moon could potentially be used to

provide elements needed to build the station

[37].

The construction also involves multiple rocket launches to transport all the necessary materials into space

[38].

The construction of a space station requires a variety of materials. These include structural

materials, thermal control materials for on-orbit and re-entry, shielding against radiation and meteoroid/space

debris impact, optics, solar arrays, lubricants, seals, and adhesives

[7].

Structural materials used in the fabrication of spacecraft hardware should be selected by

considering the operational requirements for the particular application and the design engineering properties of

the candidate materials

[7].

High strength alloys of aluminum, titanium, and stainless steel have been in common use for decades

[7].

Thermal control materials are used to moderate on-orbit temperatures. These include passive

thermal control coatings or paints, multilayer insulation (MLI) blankets, and advanced durable ceramics

[7]

[37].

Radiation shielding is a major concern for astronauts living onboard a space station. Lead is

suggested for the exterior shell and exterior window shutters due to its radiation insulating properties

[37].

Solar array materials are also crucial. The International Space Station uses silicon solar cells

with ceria-doped borosilicate cover glass for power generation

[7].

Lubricants are needed for moving mechanical assemblies exposed to the space environment. Solid

lubricants include molybdenum disulfide, tungsten disulfide, niobium diselenide, graphite powder, silver, Teflon

(polytetrafluoroethylene), and nylon

[7].

Seals are used to maintain vehicle pressurization, pneumatics, and hydraulics. These may be made

of metal or elastomer

[7].

Adhesives are used in the construction of a space station. Two classes of adhesives are used -

structural adhesives, such as those used in honeycomb laminate manufacture, and non-structural adhesives, such as

the pressure-sensitive adhesive used for thermal control tapes

[7].

The cost of materials is the same as what it would cost on Earth, plus some % that it took to

take it into space. So cheaper materials will always be cheaper than more expensive ones

[37].

The 'economy' of supply and demand is considered to be the same as well, for

simplicity's sake, so metals will not end up being the dominant force in terms of cost due to asteroid mining

[37].

The supplies needed to create the space station don't necessarily have to come from Earth.

Asteroids and other planetary bodies like the moon could provide elements needed to build the station

[37].

The construction of a space station requires a variety of materials. These include structural

materials, thermal control materials for on-orbit and re-entry, shielding against radiation and meteoroid/space

debris impact, optics, solar arrays, lubricants, seals, and adhesives

[7].

Structural materials used in the fabrication of spacecraft hardware should be selected by

considering the operational requirements for the particular application and the design engineering properties of

the candidate materials

[7].

High strength alloys of aluminum, titanium, and stainless steel have been in common use for decades

[7].

Thermal control materials are used to moderate on-orbit temperatures. These include passive

thermal control coatings or paints, multilayer insulation (MLI) blankets, and advanced durable ceramics

[7]

[37].

Radiation shielding is a major concern for astronauts living onboard a space station. Lead is

suggested for the exterior shell and exterior window shutters due to its radiation insulating properties

[37].

Solar array materials are also crucial. The International Space Station uses silicon solar cells

with ceria-doped borosilicate cover glass for power generation

[7].

Lubricants are needed for moving mechanical assemblies exposed to the space environment. Solid

lubricants include molybdenum disulfide, tungsten disulfide, niobium diselenide, graphite powder, silver, Teflon

(polytetrafluoroethylene), and nylon

[7].

Seals are used to maintain vehicle pressurization, pneumatics, and hydraulics. These may be made

of metal or elastomer

[7].

Adhesives are used in the construction of a space station. Two classes of adhesives are used -

structural adhesives, such as those used in honeycomb laminate manufacture, and non-structural adhesives, such as

the pressure-sensitive adhesive used for thermal control tapes

[7].

The cost of materials is the same as what it would cost on Earth, plus some % that it took to

take it into space. So cheaper materials will always be cheaper than more expensive ones

[37].

The 'economy' of supply and demand is considered to be the same as well, for

simplicity's sake, so metals will not end up being the dominant force in terms of cost due to asteroid mining

[37].

The supplies needed to create the space station don't necessarily have to come from Earth.

Asteroids and other planetary bodies like the moon could provide elements needed to build the station

[37].

The construction of a space-based military installation would require adherence to the Department

of Defense's Unified Facilities Criteria Program, which provides guidelines for planning, design,

construction, and operation and maintenance of real property facilities

[39].

The military construction (MILCON) program would be instrumental in planning, programming, designing, and building

the infrastructure of the installation

[40].

The construction process would also need to comply with physical security standards for the construction and

protection of Sensitive Compartmented Information Facilities (SCIFs)

[41].

The location of secure facilities and spaces within the installation would need to be strategically planned to

ensure maximum protection and security

[42].

Furthermore, any construction, development, conversion, or extension carried out with respect to the military

installation would be governed by public law, through the MILCON process

[43].

The construction of a space-based military installation would require adherence to the

Department of Defense's Unified Facilities Criteria Program, which provides guidelines for planning, design,

construction, and operation and maintenance of real property facilities

[39].

The military construction (MILCON) program would be instrumental in planning,

programming, designing, and building the infrastructure of the installation [87].

The construction process would also need to comply with physical security standards

for the construction and protection of Sensitive Compartmented Information Facilities (SCIFs) [88].

The location of secure facilities and spaces within the installation would need to be

strategically planned to ensure maximum protection and security [90].

Any construction, development, conversion, or extension carried out with respect to

the military installation would be governed by public law, through the MILCON process [91].

The MILCON process includes planning and programming facilities, determining facility project

planning, and military construction programming

[44].

The process also involves the development of MILCON projects, which includes determining

requirements, evaluating alternative solutions, and initiating programming actions

[44].

The MILCON program also requires compliance with environmental, safety, and health regulations,

as well as the consideration of sustainable design and development

[44].

The construction of a space-based military installation would also require the acquisition of

real estate interests, the provision of allowances for the physically handicapped, and the consideration of

seismic considerations

[44].

The construction process would also need to comply with airfield clearance criteria, air space

use, and joint use certification

[44].

The construction of a space-based military installation would also require the management of

solid and hazardous wastes, the consideration of environmental restoration programs, and the management of

underground storage tanks

[44].

The construction process would also need to comply with the requirements of the Air Installation

Compatible Use Zone (AICUZ) program and the Installation Development Plan (IDP)

[44].

The construction of a space-based military installation would also require the consideration of

air base survivability, conventional hardening, chemical protection levels and priorities, camouflage, concealment

and deception

[44].

The construction process would also need to comply with the requirements of the Defense Access

Road (DAR) Program, the Defense Medical MILCON, the Energy Conservation Program, the North Atlantic Treaty

Organization (NATO) Security Investment Program (NSIP), the DoD Education Activity (DoDEA), and the Emergency,

Damaged or Destroyed, and Contingency Construction Programs

[44].

The construction of a space-based military installation would also require the use of

relocatable (temporary) facilities

[44].

The construction of a space-based military installation would require adherence to the

Department of Defense's Unified Facilities Criteria Program, which provides guidelines for planning, design,

construction, and operation and maintenance of real property facilities

[39].

The military construction (MILCON) program would be instrumental in planning,

programming, designing, and building the infrastructure of the installation [87].

The construction process would also need to comply with physical security standards

for the construction and protection of Sensitive Compartmented Information Facilities (SCIFs) [88].

The location of secure facilities and spaces within the installation would need to be

strategically planned to ensure maximum protection and security [90].

Any construction, development, conversion, or extension carried out with respect to

the military installation would be governed by public law, through the MILCON process [91].

The MILCON process includes planning and programming facilities, determining facility project

planning, and military construction programming

[44].

The process also involves the development of MILCON projects, which includes determining

requirements, evaluating alternative solutions, and initiating programming actions

[44].

The MILCON program also requires compliance with environmental, safety, and health regulations,

as well as the consideration of sustainable design and development

[44].

The construction of a space-based military installation would also require the acquisition of

real estate interests, the provision of allowances for the physically handicapped, and the consideration of

seismic considerations

[44].

The construction process would also need to comply with airfield clearance criteria, air space

use, and joint use certification

[44].

The construction of a space-based military installation would also require the management of

solid and hazardous wastes, the consideration of environmental restoration programs, and the management of

underground storage tanks

[44].

The construction process would also need to comply with the requirements of the Air Installation

Compatible Use Zone (AICUZ) program and the Installation Development Plan (IDP)

[44].

The construction of a space-based military installation would also require the consideration of

air base survivability, conventional hardening, chemical protection levels and priorities, camouflage, concealment

and deception

[44].

The construction process would also need to comply with the requirements of the Defense Access

Road (DAR) Program, the Defense Medical MILCON, the Energy Conservation Program, the North Atlantic Treaty

Organization (NATO) Security Investment Program (NSIP), the DoD Education Activity (DoDEA), and the Emergency,

Damaged or Destroyed, and Contingency Construction Programs

[44].

The construction of a space-based military installation would also require the use of

relocatable (temporary) facilities

[44].

The construction of a space-based military installation would require adherence to the

Department of Defense's Unified Facilities Criteria Program, which provides guidelines for planning, design,

construction, and operation and maintenance of real property facilities

[39].

The military construction (MILCON) program would be instrumental in planning,

programming, designing, and building the infrastructure of the installation [87].

The construction process would also need to comply with physical security standards

for the construction and protection of Sensitive Compartmented Information Facilities (SCIFs) [88].

The location of secure facilities and spaces within the installation would need to be

strategically planned to ensure maximum protection and security [90].

Any construction, development, conversion, or extension carried out with respect to

the military installation would be governed by public law, through the MILCON process [91].

The MILCON process includes planning and programming facilities, determining facility

project planning, and military construction programming [82].

The process also involves the development of MILCON projects, which includes

determining requirements, evaluating alternative solutions, and initiating programming actions [82].

The MILCON program also requires compliance with environmental, safety, and health

regulations, as well as the consideration of sustainable design and development [82].

The construction of a space-based military installation would also require the

acquisition of real estate interests, the provision of allowances for the physically handicapped, and the

consideration of seismic considerations [82].

The construction process would also need to comply with airfield clearance criteria,

air space use, and joint use certification [82].

The construction of a space-based military installation would also require the

management of solid and hazardous wastes, the consideration of environmental restoration programs, and the

management of underground storage tanks [82].

The construction process would also need to comply with the requirements of the Air

Installation Compatible Use Zone (AICUZ) program and the Installation Development Plan (IDP) [82].

The construction of a space-based military installation would also require the

consideration of air base survivability, conventional hardening, chemical protection levels and priorities,

camouflage, concealment and deception [82].

The construction process would also need to comply with the requirements of the

Defense Access Road (DAR) Program, the Defense Medical MILCON, the Energy Conservation Program, the North Atlantic

Treaty Organization (NATO) Security Investment Program (NSIP), the DoD Education Activity (DoDEA), and the

Emergency, Damaged or Destroyed, and Contingency Construction Programs [82].

The construction of a space-based military installation would also require the use of

relocatable (temporary) facilities [82].

[39]

The construction of a space-based military installation would require adherence to

the Department of Defense's Unified Facilities Criteria Program, which provides guidelines for planning,

design, construction, and operation and maintenance of real property facilities [83].

The military construction (MILCON) program would be instrumental in planning,

programming, designing, and building the infrastructure of the installation [87].

The construction process would also need to comply with physical security standards

for the construction and protection of Sensitive Compartmented Information Facilities (SCIFs) [88].

The location of secure facilities and spaces within the installation would need to be

strategically planned to ensure maximum protection and security [90].

Any construction, development, conversion, or extension carried out with respect to

the military installation would be governed by public law, through the MILCON process [91].

The MILCON process includes planning and programming facilities, determining facility

project planning, and military construction programming [82].

The process also involves the development of MILCON projects, which includes

determining requirements, evaluating alternative solutions, and initiating programming actions [82].

The MILCON program also requires compliance with environmental, safety, and health

regulations, as well as the consideration of sustainable design and development [82].

The construction of a space-based military installation would also require the

acquisition of real estate interests, the provision of allowances for the physically handicapped, and the

consideration of seismic considerations [82].

The construction process would also need to comply with airfield clearance criteria,

air space use, and joint use certification [82].

The construction of a space-based military installation would also require the

management of solid and hazardous wastes, the consideration of environmental restoration programs, and the

management of underground storage tanks [82].

The construction process would also need to comply with the requirements of the Air

Installation Compatible Use Zone (AICUZ) program and the Installation Development Plan (IDP) [82].

The construction of a space-based military installation would also require the

consideration of air base survivability, conventional hardening, chemical protection levels and priorities,

camouflage, concealment and deception [82].

The construction process would also need to comply with the requirements of the

Defense Access Road (DAR) Program, the Defense Medical MILCON, the Energy Conservation Program, the North Atlantic

Treaty Organization (NATO) Security Investment Program (NSIP), the DoD Education Activity (DoDEA), and the

Emergency, Damaged or Destroyed, and Contingency Construction Programs [82].

The construction of a space-based military installation would also require the use of

relocatable (temporary) facilities [82].

[45]

The construction of a space-based military installation would require adherence to

the Department of Defense's Unified Facilities Criteria Program, which provides guidelines for planning,

design, construction, and operation and maintenance of real property facilities [83].

The military construction (MILCON) program would be instrumental in planning,

programming, designing, and building the infrastructure of the installation [87].

The construction process would also need to comply with physical security standards

for the construction and protection of Sensitive Compartmented Information Facilities (SCIFs) [88].

The location of secure facilities and spaces within the installation would need to be

strategically planned to ensure maximum protection and security [90].

Any construction, development, conversion, or extension carried out with respect to

the military installation would be governed by public law, through the MILCON process [91].

The MILCON process includes planning and programming facilities, determining facility

project planning, and military construction programming [82].

The process also involves the development of MILCON projects, which includes

determining requirements, evaluating alternative solutions, and initiating programming actions [82].

The MILCON program also requires compliance with environmental, safety, and health

regulations, as well as the consideration of sustainable design and development [82].

The construction of a space-based military installation would also require the

acquisition of real estate interests, the provision of allowances for the physically handicapped, and the

consideration of seismic considerations [82].

The construction process would also need to comply with airfield clearance criteria,

air space use, and joint use certification [82].

The construction of a space-based military installation would also require the

management of solid and hazardous wastes, the consideration of environmental restoration programs, and the

management of underground storage tanks [82].

The construction process would also need to comply with the requirements of the Air

Installation Compatible Use Zone (AICUZ) program and the Installation Development Plan (IDP) [82].

The construction of a space-based military installation would also require the

consideration of air base survivability, conventional hardening, chemical protection levels and priorities,

camouflage, concealment and deception [82].

The construction process would also need to comply with the requirements of the

Defense Access Road (DAR) Program, the Defense Medical MILCON, the Energy Conservation Program, the North Atlantic

Treaty Organization (NATO) Security Investment Program (NSIP), the DoD Education Activity (DoDEA), and the

Emergency, Damaged or Destroyed, and Contingency Construction Programs [82].

The construction of a space-based military installation would also require the use of

relocatable (temporary) facilities [82].

[45]

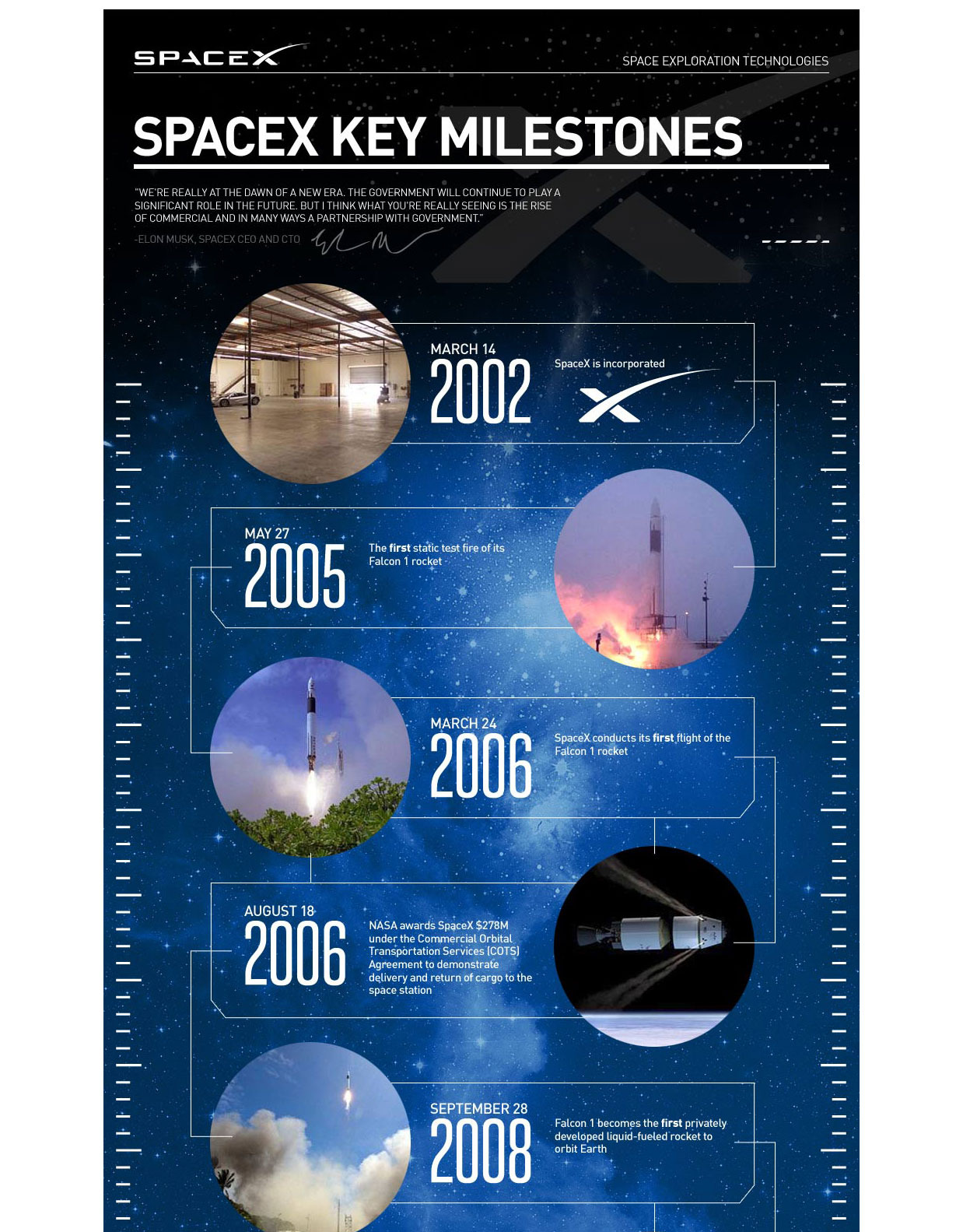

Technological Innovations and Challenges

^ top ^

Cutting-edge technologies for space station construction include the use of liquid resin to create

shapes and forms to support the construction of large structures in space

[11].

Microgravity conditions in space allow for the fabrication of longer and thinner structures without deformation,

which is a common issue on Earth due to gravity

[46].

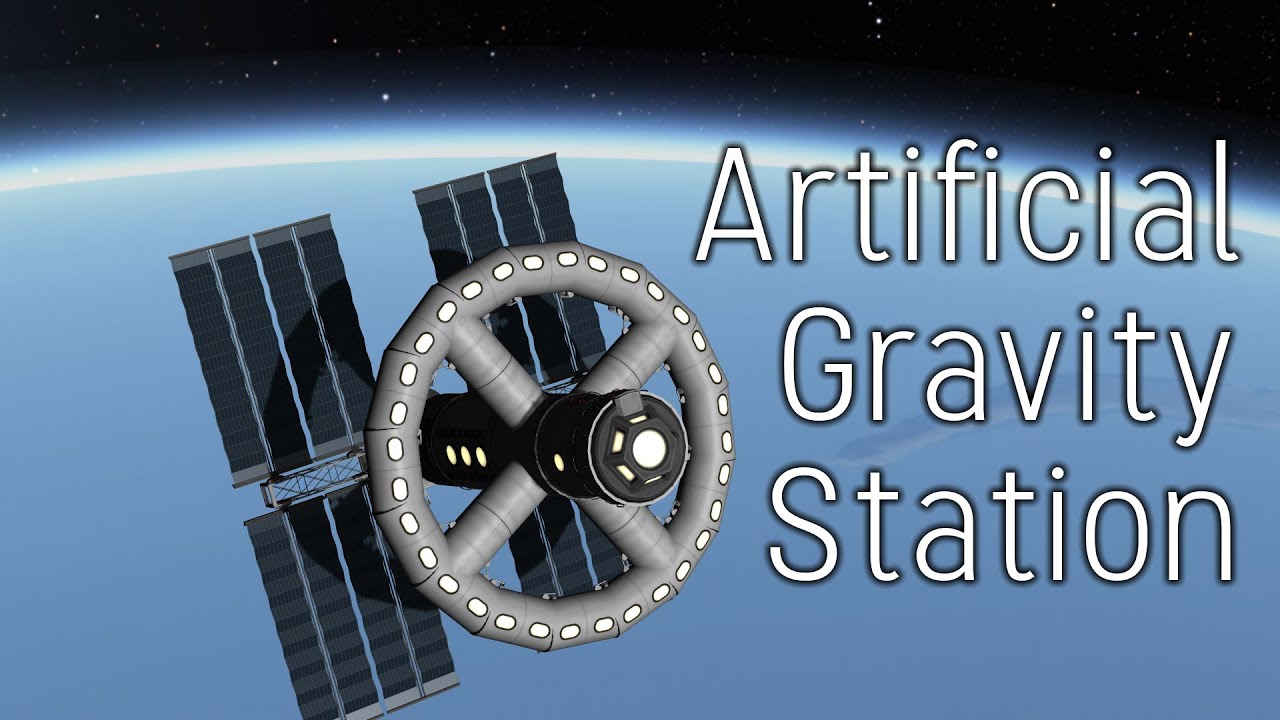

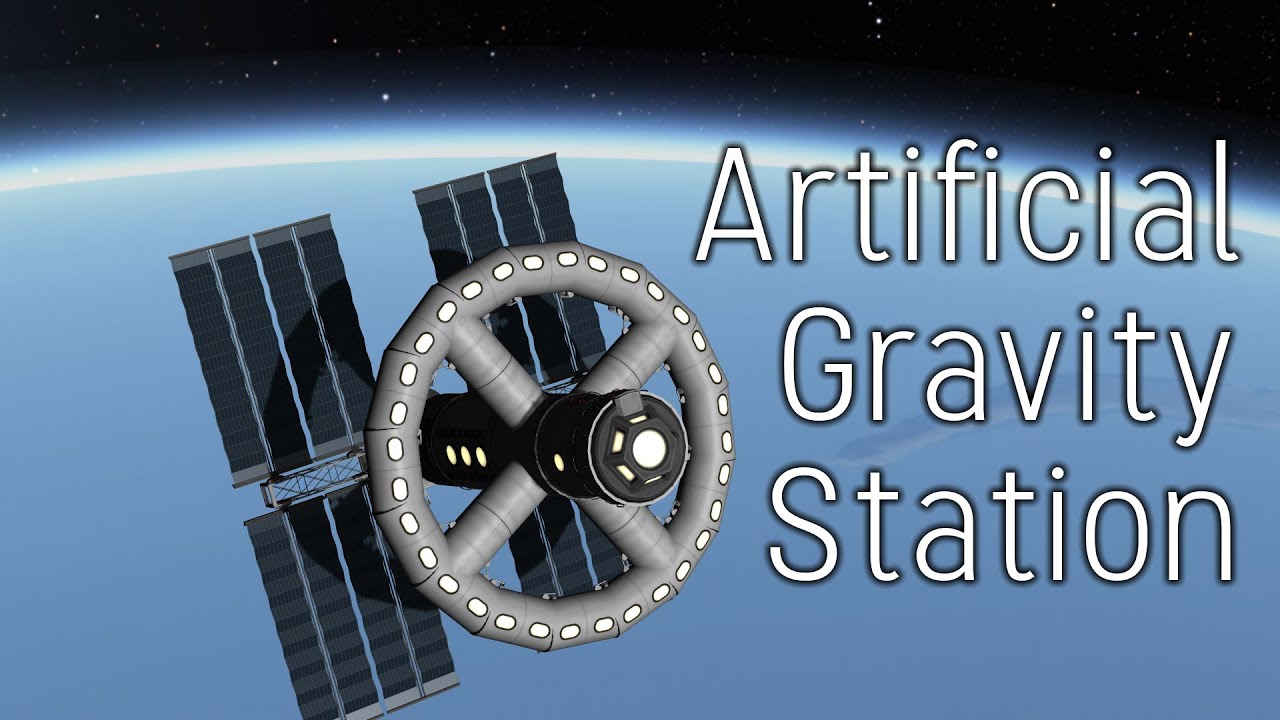

Companies are also planning to build private space stations with artificial gravity

[47].

NASA is collaborating with ICON, a construction technologies company, to develop a space-based construction system

that could support future exploration of the Moon and Mars

[12].

Furthermore, advancements in robotics, sensors, and biomedical analytical instruments are contributing to the

development of space station construction technologies

[48].

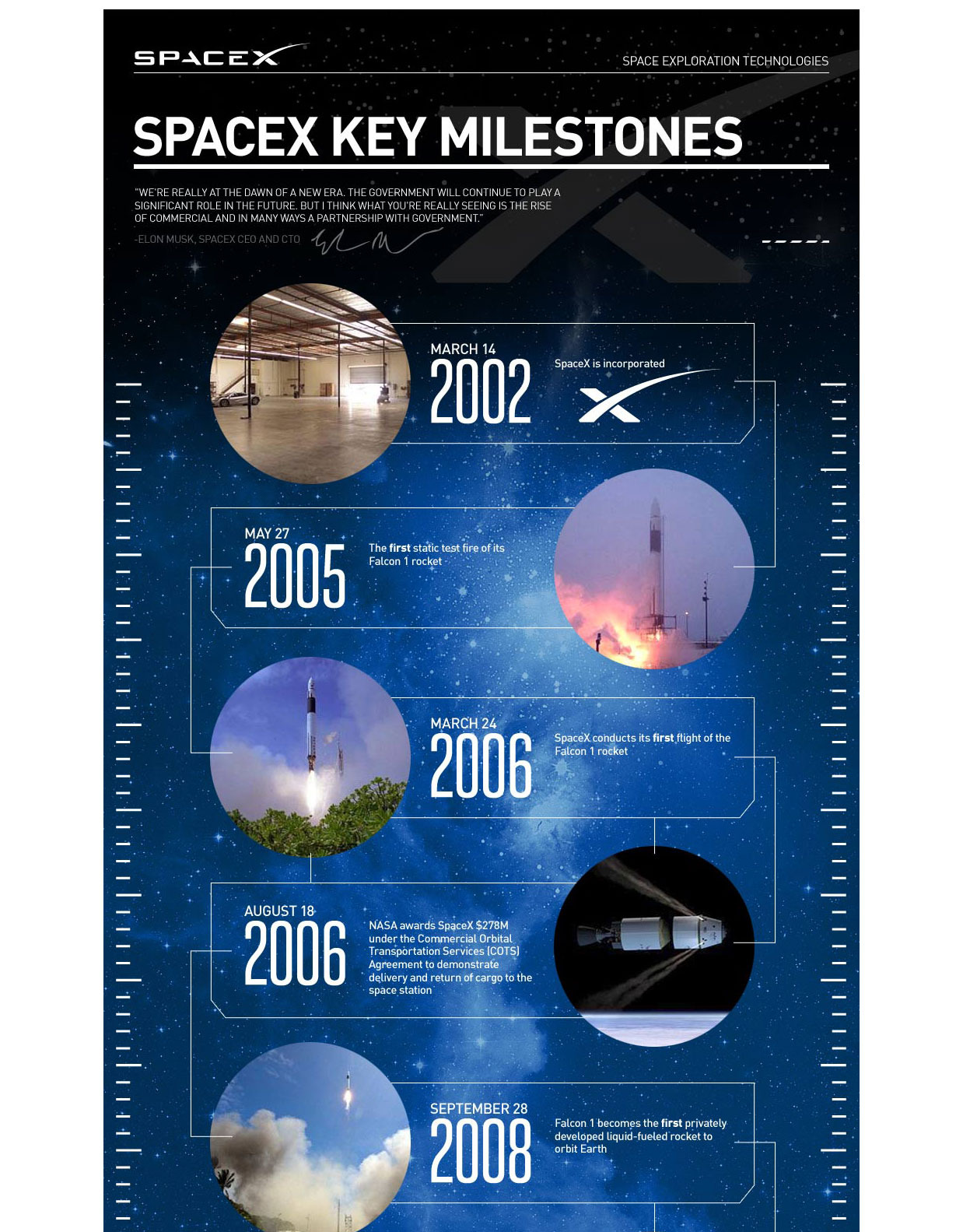

SpaceX's 26th commercial resupply mission (CRS) is set to launch a series of cutting-edge

experiments and technology demonstrations to the International Space Station. These include advancements in

in-space construction, growing plants in space, and creating nutrients on-demand

[11]

[46].

One of the key technologies being tested is the use of liquid resin to create shapes and forms

that cannot be created on Earth. This technology, known as Extrusion, leverages the microgravity environment to

produce both common and complex branching shapes, potentially supporting future space construction of large

structures like trusses and antennae

[11]

[46].

Another experiment, Veg-05, focuses on growing dwarf tomatoes in space. This research aims to

supplement the typical pre-packaged astronaut diet with fresh foods produced in space, which is essential for

long-duration exploration missions

[11]

[46].

The Moon Microscope experiment tests a kit for in-flight medical diagnosis, including a portable

hand-held microscope and a small self-contained blood sample staining device. This could provide diagnostic

capabilities for crew members in space or on the surface of the Moon or Mars

[11]

[46].

The BioNutrients-2 experiment tests a system for producing key nutrients from yogurt, kefir, and

a yeast-based beverage. This could help maintain crew health and well-being on future long-duration space missions

[11]

[46].

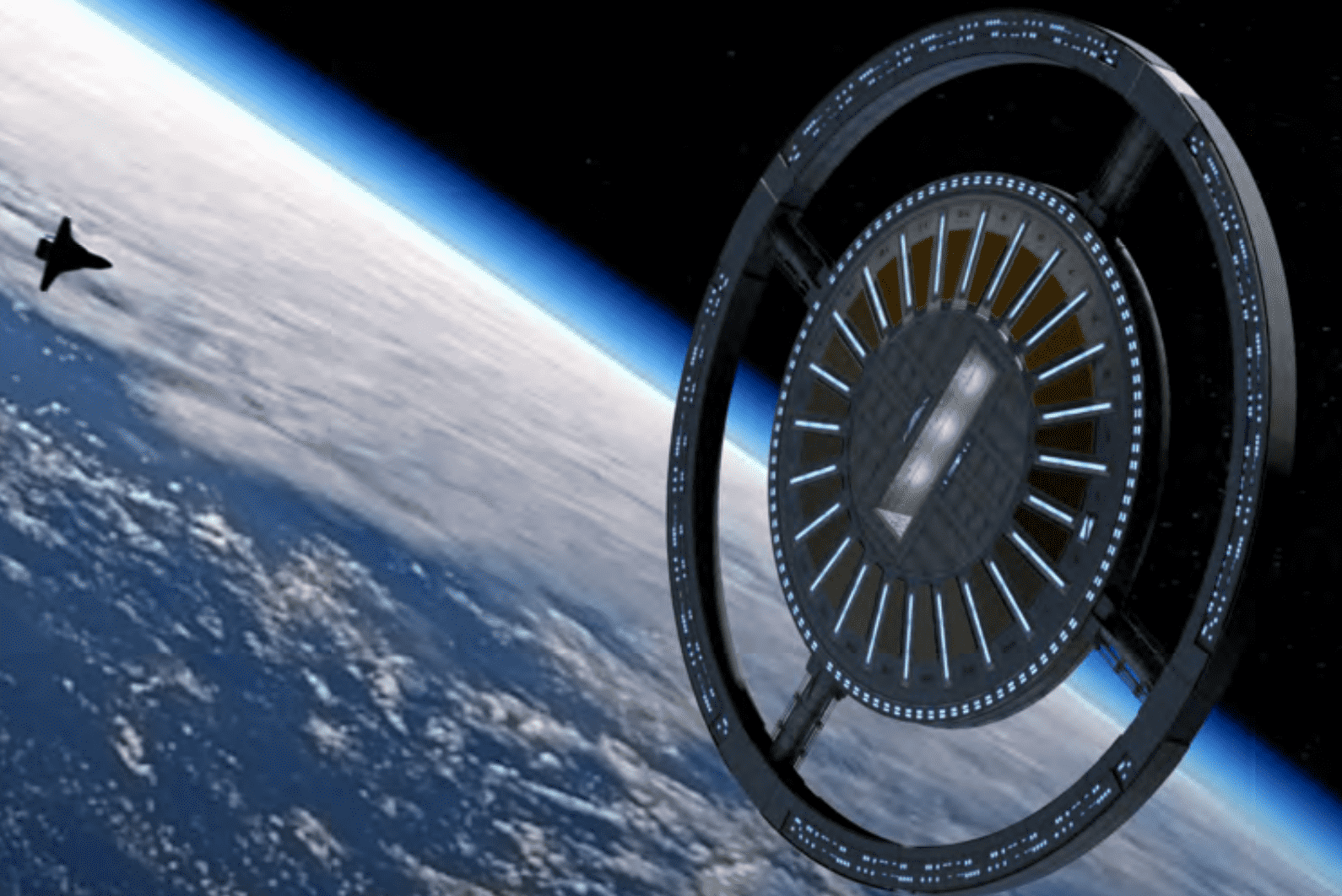

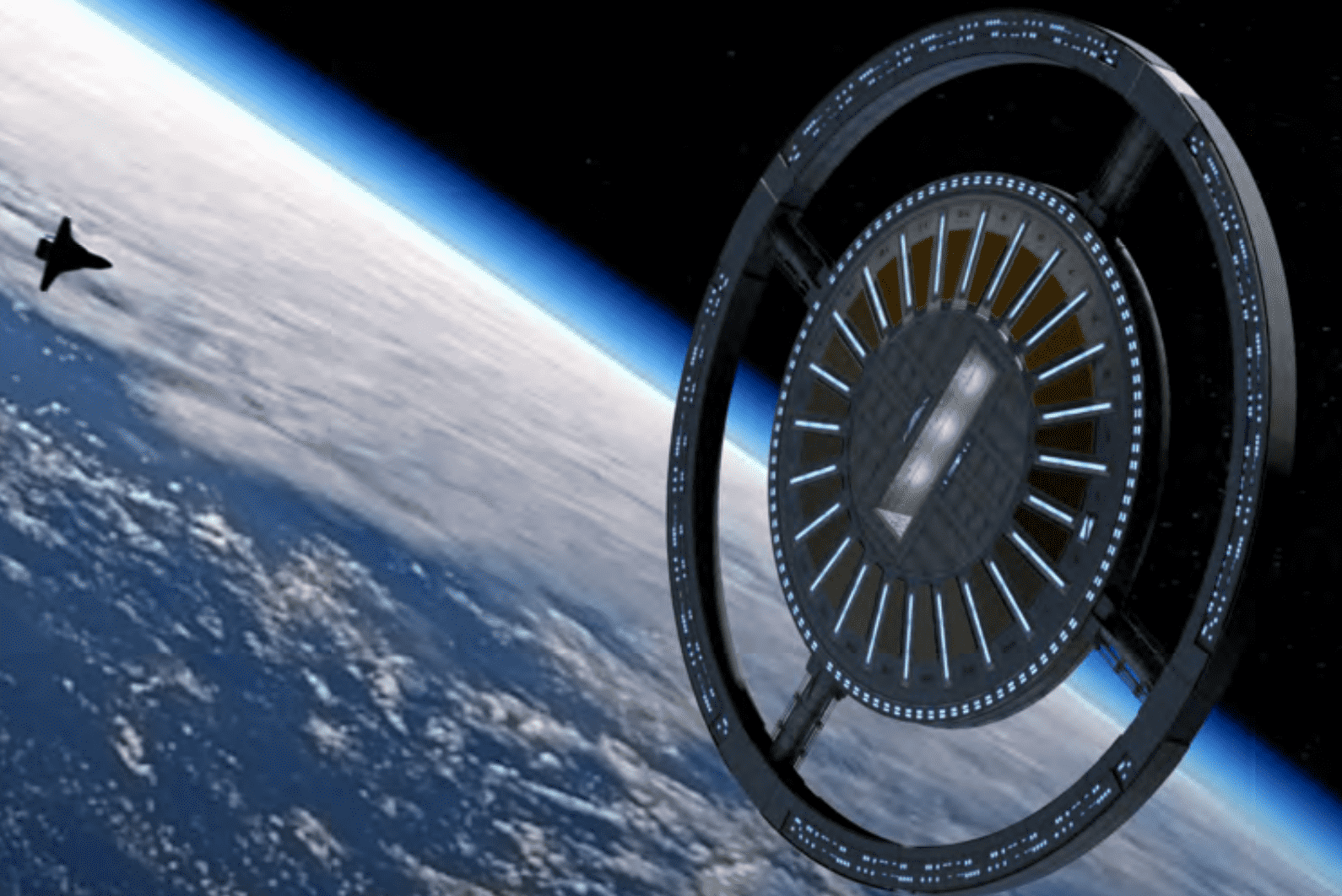

The Orbital Assembly Corporation (OAC) plans to start building the private Voyager space station

with artificial gravity in 2025. The station will be the first commercial space station operating with artificial

gravity and will be able to accommodate 400 guests

[47].

The Voyager Station will be a wheel-shaped habitat that spins to create moon-like levels of

artificial gravity for occupants. It will feature amenities ranging from themed restaurants, viewing lounges,

movie theaters, and concert venues to bars, libraries, gyms, and a health spa

[47].

Before the Voyager Station can be built, OAC plans to construct a prototype gravity ring to test

the viability of stable artificial gravity in space. This gravity ring will also serve as a research platform for

international space agencies and private aerospace firms

[47].

SpaceX's 26th commercial resupply mission (CRS) is set to launch a series of cutting-edge

experiments and technology demonstrations to the International Space Station. These include advancements in

in-space construction, growing plants in space, and creating nutrients on-demand

[11]

[46].

One of the key technologies being tested is the use of liquid resin to create shapes and forms

that cannot be created on Earth. This technology, known as Extrusion, leverages the microgravity environment to

produce both common and complex branching shapes, potentially supporting future space construction of large

structures like trusses and antennae

[11]

[46].

Another experiment, Veg-05, focuses on growing dwarf tomatoes in space. This research aims to

supplement the typical pre-packaged astronaut diet with fresh foods produced in space, which is essential for

long-duration exploration missions

[11]

[46].

The Moon Microscope experiment tests a kit for in-flight medical diagnosis, including a portable

hand-held microscope and a small self-contained blood sample staining device. This could provide diagnostic

capabilities for crew members in space or on the surface of the Moon or Mars

[11]

[46].

The BioNutrients-2 experiment tests a system for producing key nutrients from yogurt, kefir, and

a yeast-based beverage. This could help maintain crew health and well-being on future long-duration space missions

[11]

[46].

The Orbital Assembly Corporation (OAC) plans to start building the private Voyager space station

with artificial gravity in 2025. The station will be the first commercial space station operating with artificial

gravity and will be able to accommodate 400 guests

[47].

The Voyager Station will be a wheel-shaped habitat that spins to create moon-like levels of

artificial gravity for occupants. It will feature amenities ranging from themed restaurants, viewing lounges,

movie theaters, and concert venues to bars, libraries, gyms, and a health spa

[47].

Before the Voyager Station can be built, OAC plans to construct a prototype gravity ring to test

the viability of stable artificial gravity in space. This gravity ring will also serve as a research platform for

international space agencies and private aerospace firms

[47].

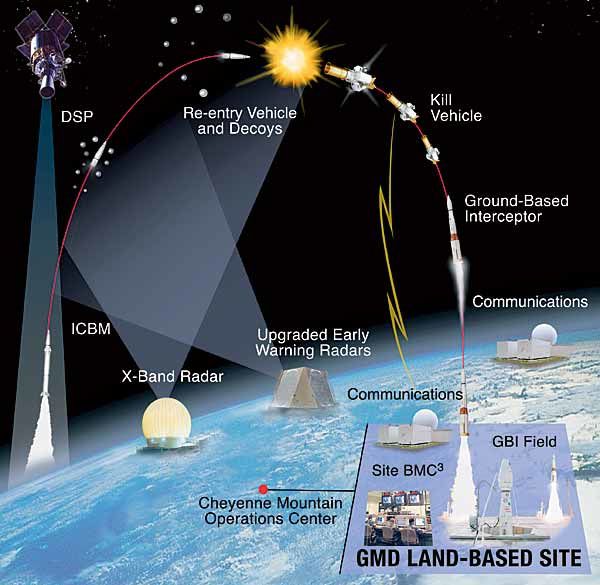

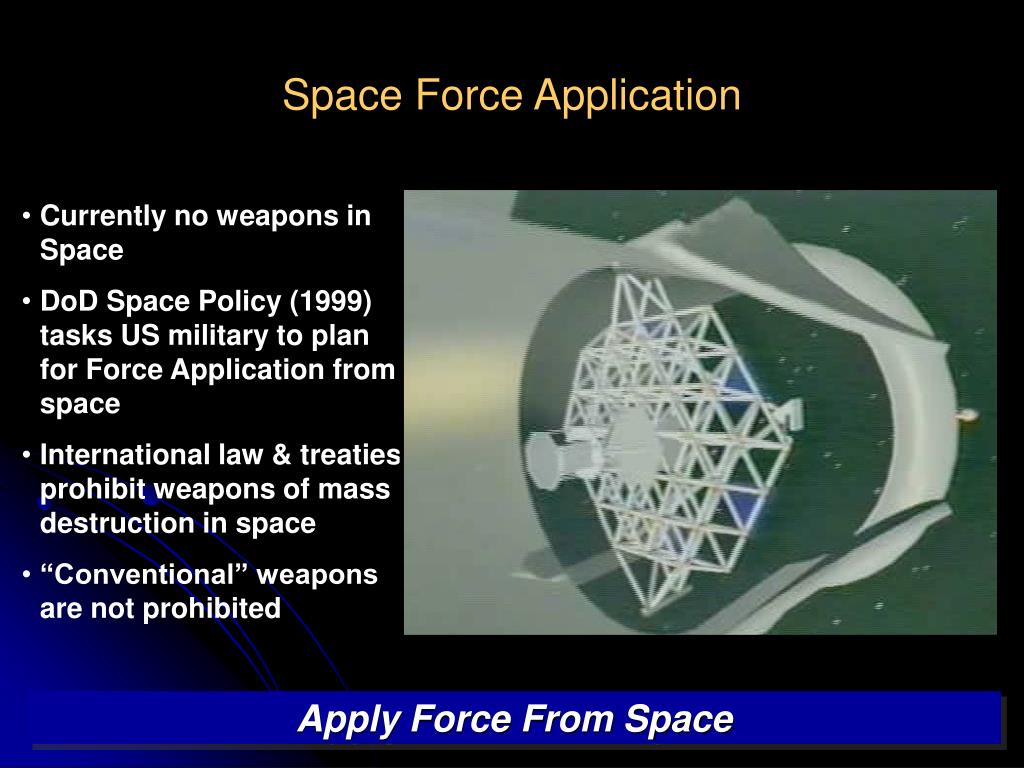

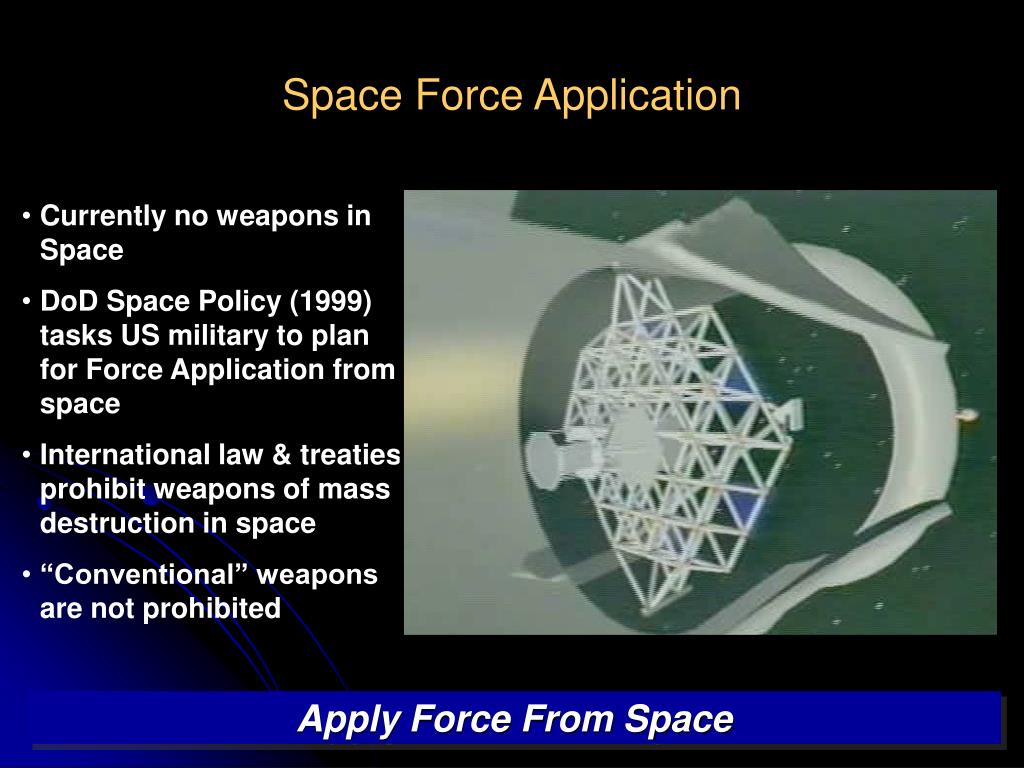

The U.S. Army is developing the world's most powerful laser weapon, which is over a million

times more powerful than any other laser developed before, capable of vaporizing targets and interrupting

adversaries' technology signals

[49].

Laser weapons have many advantages over traditional weapons, including immediate engagement of distant targets due

to transmission at the speed of light, and less collateral damage due to directed laser energy

[50].

The U.S. Army is also working with Kord Technologies to put laser weapons on the ground as part of an effort to

modernize the battlefield

[51].

Furthermore, advancements in High Energy Laser (HEL) technology and hardware are making laser weapon systems

increasingly viable

[52].

Given the advances in space weapon capabilities of China and Russia, there is a need for a new debate on the

merits of fielding U.S. space weapons

[53].

The U.S. Army is developing the world's most powerful laser weapon, known as the Tactical

Ultrashort Pulsed Laser (USPL) for Army Platforms, which is over a million times more powerful than any other

laser developed before

[49].

The USPL is capable of vaporizing targets and interrupting adversaries' technology signals

[49].

It is designed to emit short pulses that rely on low energy, unlike current lasers which typically produce

continuous waves

[49].

The U.S. Army is also working with Kord Technologies to develop ground-based laser

weapons as part of an effort to modernize the battlefield [95].

High Energy Laser (HEL) technology and hardware advancements are making laser weapon

systems increasingly viable [100].

The U.S. is also considering the development of space-based laser weapons in response

to advancements in space weapon capabilities by China and Russia [96].

The Missile Defense Agency (MDA) is putting increased emphasis on the development of

directed-energy weapons for shooting down adversary missiles

[54].

The MDA has granted Lockheed Martin a $2 million contract to explore how directed-energy weapons

might be integrated with the agency's current systems

[54].

The Biden administration's Missile Defense Review issued last October noted the need for

non-kinetic options in light of changing threats

[54].

However, the development of laser weapons faces several challenges, including the need for

technological maturation, the high cost of development, and the need for on-orbit testing

[54].

Despite these challenges, the MDA believes that the technology for laser weapons is finally

maturing, with recent tests showing impressive results

[54].

The U.S. Army is developing the world's most powerful laser weapon, known as the Tactical

Ultrashort Pulsed Laser (USPL) for Army Platforms, which is over a million times more powerful than any other

laser developed before

[49].

The USPL is capable of vaporizing targets and interrupting adversaries' technology signals

[49].

It is designed to emit short pulses that rely on low energy, unlike current lasers which typically produce

continuous waves

[49].

The U.S. Army is also working with Kord Technologies to develop ground-based laser

weapons as part of an effort to modernize the battlefield [95].

High Energy Laser (HEL) technology and hardware advancements are making laser weapon

systems increasingly viable [100].

The U.S. is also considering the development of space-based laser weapons in response

to advancements in space weapon capabilities by China and Russia [96].

The Missile Defense Agency (MDA) is putting increased emphasis on the development of

directed-energy weapons for shooting down adversary missiles

[54].

The MDA has granted Lockheed Martin a $2 million contract to explore how directed-energy weapons

might be integrated with the agency's current systems

[54].

The Biden administration's Missile Defense Review issued last October noted the need for

non-kinetic options in light of changing threats

[54].

However, the development of laser weapons faces several challenges, including the need for

technological maturation, the high cost of development, and the need for on-orbit testing

[54].

Despite these challenges, the MDA believes that the technology for laser weapons is finally

maturing, with recent tests showing impressive results

[54].

Innovations in energy generation for space stations are being explored, with a focus on both

nuclear and non-nuclear technologies

[55].

One promising concept is the Space Solar Power Station (SSPS), which involves building an extra-large solar power

station in Earth's orbit to transmit electricity to the ground wirelessly

[56]

[57].

The UK is investing in a space-based solar power development, deemed viable based on a recent report

[58].

Additionally, electric propulsion systems that use energy collected by solar arrays or nuclear reactors to

generate thrust are being developed, reducing the need for storing propellants onboard

[57].

The Department of Energy is also exploring the potential of Space-Based Solar Power (SBSP), which could

revolutionize solar power generation by collecting solar power even at night

[59].

The Department of Energy (DOE) is developing space-capable energy technologies, both nuclear and

non-nuclear, for U.S. space customers. These technologies include innovative energy generation, collection,

storage, distribution, employment, dissipation, and thermal management systems for space systems

[55].

The UK government is considering a proposal to build a solar power station in space, which is

part of the government’s Net Zero Innovation Portfolio. The space-based solar power system involves a solar

power satellite equipped with solar panels that generate electricity, which is then wirelessly transmitted to

Earth

[58].

Space-based solar power stations have the advantage of being illuminated by the Sun 24 hours a

day, allowing for continuous electricity generation. This is a significant advantage over terrestrial solar power

systems, which can only produce electricity during the day and are weather-dependent

[58].

However, there are challenges associated with space-based solar power stations. These include

the difficulty and environmental impact of transporting solar modules into space, the potential for damage from

space debris, and the degradation of solar panels due to intense solar radiation. The efficiency of wireless power

transmission is also a concern, as only a small fraction of the collected solar energy would reach Earth based on

current technology

[58].

NASA is developing in-space electric propulsion systems, which can reduce the amount of fuel

needed by up to 90% compared to chemical propulsion systems. These systems use energy collected by solar arrays or

a nuclear reactor to generate thrust, eliminating many of the needs and limitations of storing propellants onboard

[57].

Electric propulsion systems can continue accelerating for months or even years, and they can

also slow down and change direction. This provides greater mission flexibility compared to chemical propulsion

systems, which can only go in the direction they're pointing when the fuel is ignited and have limited ability

to speed up, slow down, or change direction after the fuel supply is exhausted

[57].

NASA's Power and Propulsion Element (PPE) for Gateway will demonstrate advanced, high-power

solar electric propulsion around the Moon. This system will support lunar exploration for 15 years due to its high

fuel economy and ability to move while in orbit

[57].

The Department of Energy (DOE) is developing space-capable energy technologies, both nuclear and

non-nuclear, for U.S. space customers. These technologies include innovative energy generation, collection,

storage, distribution, employment, dissipation, and thermal management systems for space systems

[55].

The UK government is considering a proposal to build a solar power station in space, which is

part of the government’s Net Zero Innovation Portfolio. The space-based solar power system involves a solar

power satellite equipped with solar panels that generate electricity, which is then wirelessly transmitted to

Earth

[58].

Space-based solar power stations have the advantage of being illuminated by the Sun 24 hours a

day, allowing for continuous electricity generation. This is a significant advantage over terrestrial solar power

systems, which can only produce electricity during the day and are weather-dependent

[58].

However, there are challenges associated with space-based solar power stations. These include

the difficulty and environmental impact of transporting solar modules into space, the potential for damage from

space debris, and the degradation of solar panels due to intense solar radiation. The efficiency of wireless power

transmission is also a concern, as only a small fraction of the collected solar energy would reach Earth based on

current technology

[58].

NASA is developing in-space electric propulsion systems, which can reduce the amount of fuel

needed by up to 90% compared to chemical propulsion systems. These systems use energy collected by solar arrays or

a nuclear reactor to generate thrust, eliminating many of the needs and limitations of storing propellants onboard

[57].

Electric propulsion systems can continue accelerating for months or even years, and they can

also slow down and change direction. This provides greater mission flexibility compared to chemical propulsion

systems, which can only go in the direction they're pointing when the fuel is ignited and have limited ability

to speed up, slow down, or change direction after the fuel supply is exhausted

[57].

NASA's Power and Propulsion Element (PPE) for Gateway will demonstrate advanced, high-power

solar electric propulsion around the Moon. This system will support lunar exploration for 15 years due to its high

fuel economy and ability to move while in orbit

[57].

NASA's Advanced Exploration Systems (AES) Life Support Systems (LSS) project is working on

developing reliable, energy-efficient, and low-mass spacecraft systems to provide environmental control and life

support systems (ECLSS) for long duration human missions beyond low Earth orbit (LEO)

[60]

[61]

[62].

These advancements are critical for future long-term crewed missions to the Moon and beyond

[63].

The life support systems are being designed to efficiently use nonrenewable resources from Earth while

increasingly relying on resources available locally in space

[64].

Even small systems, such as a working toilet or an automated fire suppression system, have to function reliably to

support life in space

[65].

The International Space Station's life support system has been extensively tested over two decades of

continuous crewed operation, providing valuable data for future advancements

[66].

Creating artificial gravity in a large-scale space station could be achieved through the use of

rotating structures, such as an O'Neill cylinder or a rotating wheel space station, which create an inertial

force that mimics the effects of a gravitational force

[67]

[68]

[69].

However, generating artificial gravity with large rotating structures poses challenges, including the need to mass

balance the entire rotating structure

[69]

[70].

Some companies are planning to build rotating space stations in stages, starting with small-scale prototypes

[47].

There are also plans to develop large-scale structures optimized for resiliency, which could potentially be used

for creating artificial gravity

[71].

Despite these advancements, artificial gravity is still largely a concept from science fiction, and significant

technological advancements would be required to make it a reality

[72].

Manpower and Skillset Requirements

^ top ^

Building a Death Star, as depicted in Star Wars, would require a vast amount of resources and

personnel. The original Death Star was said to have been constructed by millions of people over a span of 19+

years

[73].

The construction process would involve complex engineering and technical skills, including the ability to work

with fictional materials like quadanium steel

[14].

The use of construction droids, which can work continuously without the need for food and water, was a key factor

in the rapid construction of the second Death Star

[74].

Additionally, the ability to work with detailed blueprints and models, as demonstrated by Lego and model kit

versions of the Death Star, would also be necessary

[75]

[76].

The construction of the Death Star was a massive undertaking, requiring extensive planning and

resources. The first Death Star was constructed from more than 1.08×10^15 tons of steel and had a diameter

of 160km, taking over 20 years to complete

[77]

[78].

The construction process was overseen by key personnel such as Bevel Lemelisk and his engineers at the

Empire's secret Maw Installation

[79].

The plans for the Death Star were delivered from Geonosis to Coruscant by Darth Tyranus at the start of the Clone

Wars

[23].

Additionally, individuals with specific qualifications, such as Teela Kaarz, were selected to work on the Death

Star's interior design and construction

[80].

The construction of the Death Star, officially known as Orbital Battle Stations, was a massive

project undertaken by the Galactic Empire. The first Death Star was constructed from more than 1.08×10^15

tons of steel and had a diameter of 160km

[77].

The construction process was plagued by numerous challenges, including sabotage, supply chain

issues, poor project management, and resistance to the Emperor's plans

[77].

The Empire had a special advantage in the construction process: the Sanctuary Pipeline, a tunnel

through hyperspace from the Core to Endor, which significantly sped up the transportation of materials and

resources

[78].

The construction process could have been significantly improved with the use of modern

technology such as 360° reality capture, AI-powered analytics, and immersive 3D models. These tools could have

improved efficiency, communication, decision-making, and problem-solving on the construction site

[77].

The construction of the Death Star was overseen by key personnel such as Bevel Lemelisk, an

engineer, and Dak Exhaustport, an architect

[78].

Despite the massive scale and complexity of the project, the Death Star had significant design

flaws, most notably the exposed exhaust ports which ultimately led to its destruction. These flaws were attributed

to a lack of coordination between the design and engineering teams

[77].

The construction of the Death Star was a highly secretive project, with only a select few

knowing where the resources for the project were going. This secrecy, along with ongoing wars and blockades,

complicated the supply networks

[77].

The construction of the Death Star took over 20 years to complete. This long construction period

was due to its unprecedented scale, numerous challenges, and the fact that the technology for such a project was

still being developed

[77]

[78].

The construction of the Death Star, officially known as Orbital Battle Stations, was a massive

project undertaken by the Galactic Empire. The first Death Star was constructed from more than 1.08×10^15

tons of steel and had a diameter of 160km

[77].

The construction process was plagued by numerous challenges, including sabotage, supply chain

issues, poor project management, and resistance to the Emperor's plans

[77].

The Empire had a special advantage in the construction process: the Sanctuary Pipeline, a tunnel

through hyperspace from the Core to Endor, which significantly sped up the transportation of materials and

resources

[78].

The construction process could have been significantly improved with the use of modern

technology such as 360° reality capture, AI-powered analytics, and immersive 3D models. These tools could have

improved efficiency, communication, decision-making, and problem-solving on the construction site

[77].

The construction of the Death Star was overseen by key personnel such as Bevel Lemelisk, an

engineer, and Dak Exhaustport, an architect

[78].

Despite the massive scale and complexity of the project, the Death Star had significant design

flaws, most notably the exposed exhaust ports which ultimately led to its destruction. These flaws were attributed

to a lack of coordination between the design and engineering teams

[77].

The construction of the Death Star was a highly secretive project, with only a select few

knowing where the resources for the project were going. This secrecy, along with ongoing wars and blockades,

complicated the supply networks

[77].

The construction of the Death Star took over 20 years to complete. This long construction period

was due to its unprecedented scale, numerous challenges, and the fact that the technology for such a project was

still being developed

[77]

[78].

Building a space station like the Death Star would require an enormous amount of resources and

expertise. The Death Star, as depicted in Star Wars, was made from a fictional metal alloy called quadanium steel

and was crewed by 2 million Imperial personnel

[14].

The construction of such a massive structure would be a monumental task, with estimates suggesting it would take

830,000 years of Earth's current steel output to build a real-life Death Star

[81].

The Death Star was designed to be a moon-sized, deep-space mobile battle station capable of annihilating entire

planets

[82]

[1]. Therefore, the expertise needed would include advanced knowledge in various fields such as materials

science, engineering, space technology, and weapon systems.

Constructing a Death Star-like space station would require vast quantities of raw materials,

such as steel, which at current production rates would take 182 times the current age of the universe to accrue

[14].

The Death Star would require a significant power source. The International Space Station

requires about 0.75W of power for every m³ of the space station, and even with 100% efficient solar panels,

the Death Star would still be 45 times short of the ISS’s power requirements per unit volume

[14].

Creating artificial gravity on the Death Star could be achieved by spinning the station to

create centrifugal forces. However, this would call into question the Death Star’s spherical design as the

centrifugal force is proportional to the radius of the circular path, meaning gravity would start to vanish

towards the center of the station or towards the poles

[14].

The concept of a Dyson sphere, a megastructure that harnesses all the energy from a star, could

potentially solve the gravity problem. However, Dyson spheres usually run into problems due to immense stresses

from gravitational forces

[14].

The use of nuclear fusion could provide enough power for the Death Star. However, the pressures

involved inside the reactor would be immense, requiring the use of some of the strongest magnetic fields in the

universe to contain the fusion plasma

[14].

The cost of constructing a Death Star is estimated to be $850 quadrillion, many times the U.S.

national debt of about $20 trillion

[81].

The best way to build a Death Star would likely be to mine asteroids and possibly the moon for

metals, print the massive parts, and then transport them to the neighborhood of the Earth

[81].

The Death Star's laser would require an output many times that of our sun, an extraordinary

amount of energy

[83].

The construction of a Death Star would also require a huge space industry infrastructure,

including the ability to launch many more rockets than we can today, and asteroid mining

[81].

The builders of the Death Star would be exposed to harmful ionizing radiation from space because

they would be outside Earth's protective atmosphere and magnetic field

[81].

Constructing a Death Star-like space station would require vast quantities of raw materials,

such as steel, which at current production rates would take 182 times the current age of the universe to accrue

[14].

The Death Star would require a significant power source. The International Space Station

requires about 0.75W of power for every m³ of the space station, and even with 100% efficient solar panels,

the Death Star would still be 45 times short of the ISS’s power requirements per unit volume

[14].

Creating artificial gravity on the Death Star could be achieved by spinning the station to

create centrifugal forces. However, this would call into question the Death Star’s spherical design as the

centrifugal force is proportional to the radius of the circular path, meaning gravity would start to vanish

towards the center of the station or towards the poles

[14].

The concept of a Dyson sphere, a megastructure that harnesses all the energy from a star, could

potentially solve the gravity problem. However, Dyson spheres usually run into problems due to immense stresses

from gravitational forces

[14].

The use of nuclear fusion could provide enough power for the Death Star. However, the pressures

involved inside the reactor would be immense, requiring the use of some of the strongest magnetic fields in the

universe to contain the fusion plasma

[14].

The cost of constructing a Death Star is estimated to be $850 quadrillion, many times the U.S.

national debt of about $20 trillion

[81].

The best way to build a Death Star would likely be to mine asteroids and possibly the moon for

metals, print the massive parts, and then transport them to the neighborhood of the Earth

[81].

The Death Star's laser would require an output many times that of our sun, an extraordinary

amount of energy

[83].

The construction of a Death Star would also require a huge space industry infrastructure,

including the ability to launch many more rockets than we can today, and asteroid mining

[81].

The builders of the Death Star would be exposed to harmful ionizing radiation from space because

they would be outside Earth's protective atmosphere and magnetic field

[81].

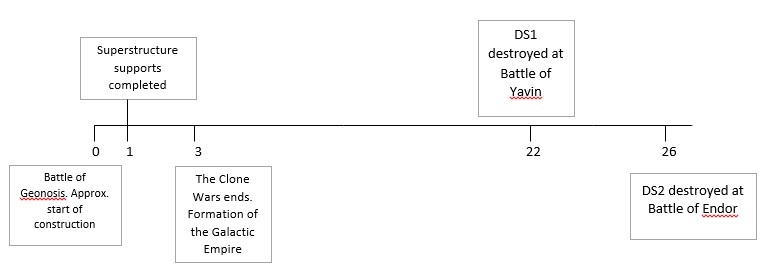

Project Timeline and Milestones

^ top ^

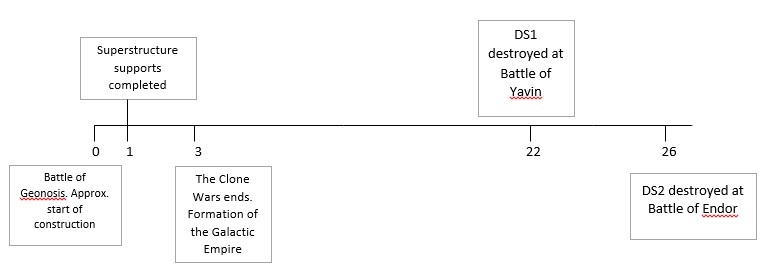

The construction of the first Death Star began at the end of Episode III, around 19 BBY, and was

completed about 1 BBY, taking approximately 18 to 20 years to build

[15]

[16].

The Death Star was a moon-sized, deep-space mobile battle station constructed by the Galactic Empire, costing over

1 trillion galactic credits

[82]

[84].

The construction project was initiated to revolutionize Galactic governance, with the Emperor showing no personal

interest in the day-to-day affairs of the Empire

[85].

The Empire completed the construction of the Death Star, but Rebel Alliance spies managed to steal data tapes

containing its schematics, aiming to find a weakness within the superstructure and exploit it

[23].

The construction of the Death Star was a significant event across the Star Wars timeline, demonstrating the slow

and looming creation of this technological terror

[86].

The first Death Star began construction around 19 BBY (Before the Battle of Yavin), as seen at

the end of Episode III

[15]

[16].

The construction process was lengthy due to the sheer size and complexity of the Death Star, as well as the need

for secrecy during the early stages of its construction

[16].

The first Death Star was completed around 1 BBY (Before the Battle of Yavin), taking approximately 18 to 20 years

to build

[15]

[16].

The second Death Star's construction started during the Battle of Yavin, shortly before the

first Death Star's destruction

[15].

Despite the second Death Star being significantly larger than the first, it was built in a much shorter time

frame, with significant progress made by 4 ABY (After the Battle of Yavin)

[15]

[85].

This accelerated construction timeline is attributed to the Empire's experience and knowledge gained from the

construction of the first Death Star, as well as the allocation of more resources and manpower

[15].

There is some speculation that the second Death Star was a repaired and refurbished version of

the first one, but this claim lacks substantial evidence and is contradicted by the fact that the first Death Star

was completely destroyed

[15].

The Death Star projects were not only significant for their military power but also for their

political implications. The construction of the first Death Star began under the guise of the Confederacy of

Independent Systems/Separatists, before the Empire was even founded, as part of Emperor Palpatine's long-term

plans for dictatorship

[16].

The second Death Star's construction, on the other hand, was more openly conducted after the Emperor had

dissolved the senate and gained unlimited power

[15].

The first Death Star began construction around 19 BBY (Before the Battle of Yavin), as seen at

the end of Episode III

[15]

[16].

The construction process was lengthy due to the sheer size and complexity of the Death Star, as well as the need

for secrecy during the early stages of its construction

[16].

The first Death Star was completed around 1 BBY (Before the Battle of Yavin), taking approximately 18 to 20 years

to build

[15]

[16].

The second Death Star's construction started during the Battle of Yavin, shortly before the

first Death Star's destruction

[15].

Despite the second Death Star being significantly larger than the first, it was built in a much shorter time

frame, with significant progress made by 4 ABY (After the Battle of Yavin)

[15]

[85].

This accelerated construction timeline is attributed to the Empire's experience and knowledge gained from the

construction of the first Death Star, as well as the allocation of more resources and manpower

[15].

There is some speculation that the second Death Star was a repaired and refurbished version of

the first one, but this claim lacks substantial evidence and is contradicted by the fact that the first Death Star

was completely destroyed

[15].

The Death Star projects were not only significant for their military power but also for their

political implications. The construction of the first Death Star began under the guise of the Confederacy of

Independent Systems/Separatists, before the Empire was even founded, as part of Emperor Palpatine's long-term

plans for dictatorship

[16].

The second Death Star's construction, on the other hand, was more openly conducted after the Emperor had

dissolved the senate and gained unlimited power

[15].

Building large-scale space stations involves several key milestones. One of these is the

development of new low Earth orbit commercial space stations by four U.S. companies, which is a significant step

in continuing NASA's research and technology development after the retirement of the International Space

Station

[87].

Another milestone is the successful completion of the second sub-scale Ultimate Burst Pressure (UBP) test by

Sierra Space for their LIFE™ habitat, a part of their end-to-end business and technology platform in space

[88].

Sierra Space also announced a pioneering full-scale "Burst Test" of their softgoods structure, marking a

significant milestone in the development of the world's first commercial space station, Orbital Reef

[89]

[90].

Furthermore, the concept of self-assembling large-scale space structures is being tested and worked towards, with

one of the selected projects being flown on an ISS mission

[91].

Four U.S. companies are making progress on new low Earth orbit commercial space stations for

NASA to continue its research and technology development after the retirement of the International Space Station

[87].

NASA contracted with Axiom Space in 2020 to provide a habitable commercial module to attach to

the International Space Station. Axiom Space is on track to launch its first module to the International Space

Station by 2026

[87].

In December 2021, NASA awarded space act agreements to Blue Origin, Nanoracks, and Northrop

Grumman to develop free-flying space destinations

[87].

Sierra Space, a partner of Blue Origin, passed a successful test milestone on a key piece of its

space station, the LIFE (Large Integrated Flexible Environment) module

[87].

Sierra Space successfully completed its second sub-scale Ultimate Burst Pressure (UBP) test for

the LIFE habitat, establishing the company as a leader in commercial space station development

[88].

Sierra Space announced a pioneering full-scale "Burst Test" of their softgoods

structure, marking a significant milestone in the development of the world's first commercial space station,

Orbital Reef

[89].

Sierra Space's LIFE habitat is a three-story commercial habitation and science platform

designed for low-Earth orbit (LEO) that will allow humans to live and work comfortably in space

[88].

Sierra Space's expandable space station module technology is highly scalable and flexible to

all existing and planned launch vehicle fairing sizes

[89].

Full-scale LIFE UBP tests will begin in 2023, in order to complete NASA’s certification of

the habitat’s primary structure for human use in space

[88].

Sierra Space is also building an array of in-space destinations for low-Earth orbit (LEO)

commercialization including the LIFE™ habitat (Large Integrated Flexible Environment), a three-story

commercial habitation and science platform designed for LEO

[88].

Both Dream Chaser and LIFE are central components to Orbital Reef, a mixed-use business park in

LEO being developed by principal partners Sierra Space and Blue Origin, which is expected to be operational by the

end of the decade

[88].

Four U.S. companies are making progress on new low Earth orbit commercial space stations for

NASA to continue its research and technology development after the retirement of the International Space Station

[87].

NASA contracted with Axiom Space in 2020 to provide a habitable commercial module to attach to

the International Space Station. Axiom Space is on track to launch its first module to the International Space

Station by 2026

[87].

In December 2021, NASA awarded space act agreements to Blue Origin, Nanoracks, and Northrop

Grumman to develop free-flying space destinations

[87].

Sierra Space, a partner of Blue Origin, passed a successful test milestone on a key piece of its

space station, the LIFE (Large Integrated Flexible Environment) module

[87].

Sierra Space successfully completed its second sub-scale Ultimate Burst Pressure (UBP) test for

the LIFE habitat, establishing the company as a leader in commercial space station development

[88].

Sierra Space announced a pioneering full-scale "Burst Test" of their softgoods

structure, marking a significant milestone in the development of the world's first commercial space station,

Orbital Reef

[89].

Sierra Space's LIFE habitat is a three-story commercial habitation and science platform

designed for low-Earth orbit (LEO) that will allow humans to live and work comfortably in space

[88].

Sierra Space's expandable space station module technology is highly scalable and flexible to

all existing and planned launch vehicle fairing sizes

[89].

Full-scale LIFE UBP tests will begin in 2023, in order to complete NASA’s certification of

the habitat’s primary structure for human use in space

[88].

Sierra Space is also building an array of in-space destinations for low-Earth orbit (LEO)

commercialization including the LIFE™ habitat (Large Integrated Flexible Environment), a three-story

commercial habitation and science platform designed for LEO

[88].

Both Dream Chaser and LIFE are central components to Orbital Reef, a mixed-use business park in

LEO being developed by principal partners Sierra Space and Blue Origin, which is expected to be operational by the

end of the decade

[88].

Managing large-scale construction projects effectively requires a dynamic approach and special

management strategies

[92].

It is crucial to have senior project managers who can identify inefficiencies and make necessary adjustments

[93].

The use of technology, such as scheduling software, can aid in detailing tasks and managing timelines

[93].

However, it's also important to have a consistent approach to developing successful megaprojects, which often

have high value, long timelines, and high risk

[94].

Learning from both successful and unsuccessful projects can improve outcomes and benefit the infrastructure

industry and the communities it serves

[95].

Effective reporting and control mechanisms are also essential for managing large capital projects

[96].

Lessons learned from previous space station construction projects highlight the importance of

safety in materials design, manufacturing, testing, launch, assembly, and operations

[97].

One significant lesson is the value of recycling to make spaceflight more affordable, as demonstrated by the reuse

of all water produced on the station, including human urine and sweat

[98].

Another key lesson pertains to the use of Leak Before Burst (LBB) criteria versus safe-life criteria as a design

tool for complex fracture critical welded structures

[99].

These lessons, along with others, should be systematically incorporated into subsequent projects to improve

knowledge management and learning culture

[100].

Furthermore, documenting these lessons accurately can help future project managers learn from past mistakes and

successes

[101].

The NASA Lessons Learned system is a database that contains official, reviewed lessons from NASA

programs and projects, including space station construction projects. This system is managed by the NASA Lessons

Learned Steering Committee and is accessible to the public

[102].

The International Space Station (ISS) program, initiated in 1994, has provided numerous lessons

regarding the safety of materials. These lessons range from flammability evaluation of materials, toxicity

findings for foams, compatibility testing for materials in fluid systems, and contamination control in precision

clean systems and critical space vehicle surfaces

[97].

Flammability testing methodology has been a significant area of research. It has been found that

materials' combustion characteristics in microgravity are quite different than those observed using standard

test methods. The best response to an on-orbit combustion event is to cut power and ventilation

[97].

Oxygen concentration conditions of operation set the oxygen concentration used for materials